Saturday Feb 28, 2026

Saturday Feb 28, 2026

Monday, 14 September 2020 02:57 - - {{hitsCtrl.values.hits}}

By Charumini de Silva

The Fabric and Apparel Accessory Manufacturers Association (FAAMA) is urging the Government to reduce prices of furnace oil as it impacts competitiveness and deprives the country from saving valuable foreign exchange.

The Fabric and Apparel Accessory Manufacturers Association (FAAMA) is urging the Government to reduce prices of furnace oil as it impacts competitiveness and deprives the country from saving valuable foreign exchange.

FAAMA made this request at a recently held forum on Sri Lanka’s Export Development and Way Forward, chaired by Trade Minister Bandula Gunawardena at NSBM Green University in Homagama.

FAAMA pointed out that Sri Lanka needs at least $3.3 billion worth of fabric and accessories to cater to the $5.1 billion export market, but the country only produces $550 million worth of fabric and accessories at present.

Therefore, fabrics and accessories worth $ 2.8 billion are still dependent on imports (under CH Code 50 to 60). This is further classified into apparel manufacturing for export and for domestic purposes with associated imports of $ 1.6 billion and $ 1.2 billion, respectively.

"This shows that Sri Lanka has the opportunity to save foreign exchange to the extent of $ 2.8 billion annually," the FAAMA said.

It also estimates that the capability in the local textile and apparel accessories industry can cater to around $ 2 billion annually.

This can be possible if adequate infrastructure is in place and a competitive utility cost is afforded to the industry. Utility/energy accounts for 30% of the total cost in textile manufacturing.

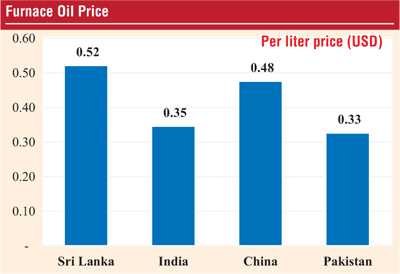

“Processing of fabric and accessories requires a large amount of furnace oil, but it is very expensive in Sri Lanka compared to other regional markets like India and Pakistan. This is a major challenge for our competitiveness,” FAAMA stressed.

Currently many manufacturers are using Biomass Boilers, which have a higher carbon footprint, but are cheap. Accordingly, biomass boilers only require Rs. 500,000 worth of wood while furnace oil requirement is Rs. 3 million.

They requested the Government to discuss with the Ceylon Petroleum Corporation (CPC) and provide furnace oil at a better rate.

The industry is also calling for cost-effective and sustainable waste disposal methodology, including a central incineration facility, and to redress limitations in infrastructure and waste management capabilities in the Biyagama and Avissawella industrial parks.