Sunday Feb 22, 2026

Sunday Feb 22, 2026

Tuesday, 10 May 2016 00:04 - - {{hitsCtrl.values.hits}}

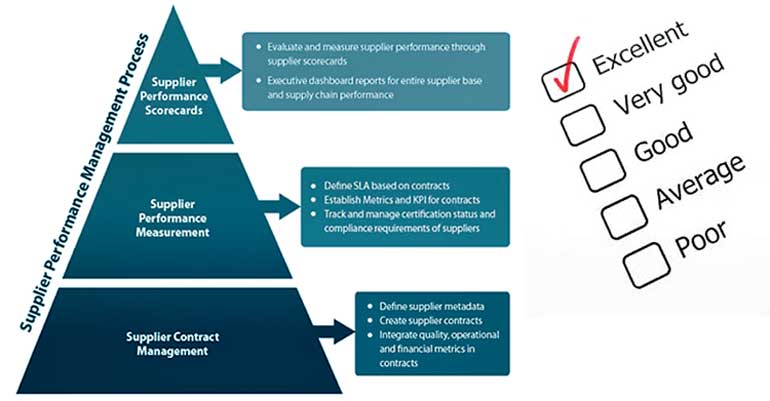

Regularly tracking your relationship with your suppliers and their performance toward your expectations is critical to ensure the success of your business. One mechanism for tracking this is the supplier scorecard. A scorecard is in essence a report card for your supplier. Supplier scorecards when used effectively can help maintain a healthy supply chain and will benefit both parties. If not used effectively supplier scorecards can damage the supplier relationship and hurt both businesses.

Effective scorecards should use meaningful metrics. If it doesn’t align with business goals then it shouldn’t be measured. Easily measured variables of no importance will just cause clutter; they could also cause a supplier to focus their performance in areas that do not matter. If the metrics are not clearly defined and understood by the suppliers then it will be hard for them to adjust their performance in these areas. Another consideration is there may be things that are important to you which your suppliers have no way of measuring or attaining the performance you are asking for.

As with all business to business relationships communication is critical for maintaining and improving supplier performance. To ensure suppliers meet your needs you should communicate to them from the offset how their performance will be measured. You can even tie bonuses and penalties into their performance scores. You should be mindful that your relationship with your supplier should be collaborative; as you grow so should they. You should share the results of your scorecards with your suppliers on a regular basis and shouldn’t wait until a review to raise a concern.

Another important aspect of communication is sharing your business objectives and performance data with your suppliers. This can help them to better shape their business to meet your needs as your business fluctuates.

It is important when evaluating suppliers to have a good process in place for tracking important metrics. When possible it is best to use accurate data that is understood by both you and your supplier. If you use irrelevant metrics which are subjective then improvements become difficult to measure and target. Also, tracking metrics throughout the scoring period will help to ensure the data is accurate and your scorecard reflects actual performance.

When dealing with different suppliers it is important to make sure the metrics you are evaluating are relevant to each supplier. As a result it is not recommended to use a one size fits all approach to supplier scorecards. Another thing to keep in mind is that you may be sourcing from the same supplier through multiple locations. It is important to track each of these on its own scorecard to help your supplier learn where they are doing things right and where they are falling short of your expectations.

Certain organisations have several strategic supplier partnerships. The way they manage supplier relationships is through quarterly business reviews with each of our partners. In these meetings high level representation from both companies is present. We share with our partners our business results and forecasts in addition to any major company news. After sharing this information we review our scorecard process with the suppliers, show a score card comparison, take a detailed look at each rating, and then provide an overall summary.

Scoring system looks at aspects of quality, delivery, cost, support, and inventory management. With respect to quality we look at hard numbers like failures out of the box and returns from our customers. We take into account both product quality and process quality. When it comes to delivery we measure on-time delivery, missed shipments, and lead times. Some of our customers have long term fixed cost agreements so this metric isn’t required, for others the cost fluctuates; we measure whether or not their costs are in line with our expectations. Support has several levels including technical support, order support, and special cases. Inventory management tracks how well they are able to maintain some inventory on hand for us.

The scorecard metrics used to be scored on the basis of a five point scale from far below expectations to far above expectations. After running through several of these scorecards we determine that it was not likely to get exceeds expectations because the only time expectations could be exceeded is if our demand was well above our forecasts. Since this goal wasn’t something attainable by a supplier of their own action we adjusted our scorecard to have only three levels, from below expectations to meets expectations.

The scorecard comparison is unique to the supplier and it shows the ratings for each of the metrics for the current review period as well as four prior quarters. We display this in a colour coded matrix so that it is easy to see where each metric is improving, staying the same, or regressing from period to period. For the employer these quarterly business reviews give us frequent touch points with the suppliers. This helps us to identify issues and areas for improvement to strengthen our supplier relationships and our business.

Throughout this article we have able to hit on several best practices with respect to supplier scorecards. Further we need to stress that this is just a tool. The fact that you have a scorecard system in place should not prevent you from acting immediately if issues present themselves. After all, this should be a collaborative exercise which will benefit both your company as well as your suppliers. In addition it is important to solicit internal feedback from interested parties. Supplier scorecards should be used to make decisions about whether or not to continue supplier relations or to pursue alternative suppliers.