Saturday Feb 21, 2026

Saturday Feb 21, 2026

Thursday, 21 July 2022 01:40 - - {{hitsCtrl.values.hits}}

As Sri Lanka seeks to generate urgently-needed foreign exchange, the pioneering example of Regional Plantation Companies (RPCs) like Malwatte Valley Plantations PLC (MVP) may serve to shine a light on the forward-looking strategies necessary to boost export performance at national level.

As Sri Lanka seeks to generate urgently-needed foreign exchange, the pioneering example of Regional Plantation Companies (RPCs) like Malwatte Valley Plantations PLC (MVP) may serve to shine a light on the forward-looking strategies necessary to boost export performance at national level.

Like most of Sri Lanka’s RPCs, when MVP was first established in 1992, the company was solely engaged in the cultivation of tea and rubber.

Strength in diversity

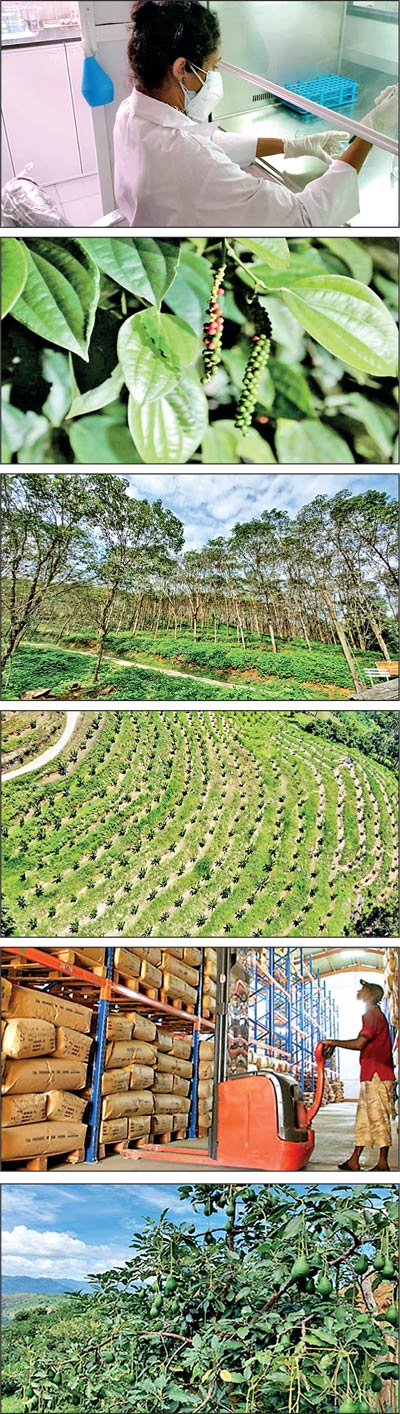

However, in the decades that followed, MVP has evolved into a seamless grower, manufacturer and exporter of not just tea and rubber but also an extensive range of fruits, herbs and spices.

These include avocado mandarin, rambutan and durian cultivations. Similarly, in spices, MVP now operates Sri Lanka’s single largest black pepper cultivation, in addition to growing other valuable spices including premium Ceylon cinnamon, cardamom, and vanilla, all of which can now be found on supermarket shelves locally under the ‘Malwatte’ brand.

“Our ambitious investments in crop diversification will yield good returns in the near future. We generate around 40% of our revenue in foreign currency. While a majority of these earnings are still generated by the company’s premium tea business, it is envisaged that a growing portion of this will soon come from direct exports of our diversified crops.

“These earnings have been extremely helpful for the company in navigating the current issues in the domestic market. If these efforts can be scaled up across the entire Sri Lankan plantation sector, there is still tremendous room for growth,” Malwatte Valley Plantations Managing Director Lucas Bogtstra notes.

Exporting the essence of tea

MVP’s diversification strategy goes beyond the crops that it cultivates. Leveraging its investments in Research and Development (R&D), the company is also pioneering an entirely new line of products that promises to shift Ceylon Tea into being more than just a beverage.

Working in partnership with a reputed German company and after many years of trials, MVP is developing an innovative range of tea-based cosmetics from face and body creams to shampoos, body washes and many more.

Similarly, MVP is currently in discussions with another Austrian company in order to produce cinnamon oil and other extracts, leveraging on similar extraction processes pioneered by the Austrian partner. Possibilities are being explored to develop similar products using herbs and spices grown by the company or procured from its smallholder farmers.

“We believe the next frontier for Sri Lankan plantations is leveraging science and technology to optimise production while adding value to create new products. Of course, there will always be a place for tea, as it has been traditionally consumed for centuries.”

“But we must also understand that with the capabilities available to us today, Sri Lanka has the unique potential to drastically expand the performance of its plantations and agribusinesses by moving up and across the value chain as well. This is a veritable gold mine for our nation, and it is incumbent on all stakeholders to explore these avenues for untapped growth,” Bogtstra stated.

Notably, since crops like cinnamon are mostly grown by smallholders, commercial-scale cultivators also have the potential to aggregate produce and verify standards on behalf of their international suppliers. This enables further competitive advantage in terms of traceability, as it can become difficult for brands to verify the origins of material sourced from many farmers.

“Complementing our innovations in product development and diversification, we are also strengthening the efficiency of our operations through mechanisation and machine learning,” Malwatte Valley Plantations Director/CEO Shanaka Samaradiwakara noted.

“Beyond cost savings and environmental benefits stemming from the saving of energy, this is vital in ensuring the future sustainability of our operations, since there is a severe shortage of employees in the plantation sector.”

Malwatte Valley has invested more than Rs. 2.683 billion since 1992 to enhance productivity and efficiency at both plantation and factory level. The company is working on introducing a smart withering solution to its estates.

Withering is the most energy-intensive phase, accounting for almost 60% of energy consumption during tea production. Tea leaves can also be damaged during this phase, as they have to be turned from side to side during the conventional withering process.

Malwatte Valley’s innovative mechanism will eliminate the manual turning of leaf whilst using dry air to remove moisture. This will also reduce energy consumption by 30% to 40%, saving around 750-800 MT of greenhouse gas (GHG) emissions annually.

The company’s in-house electronic and mechanical R&D laboratory is also experimenting with using image recognition technology to identify the best quality tea leaves for harvesting using machines, thus improving the tea plucking process. The company intends to extend its mechanisation initiatives from tea to other crops, including the possible peeling of cinnamon in the future.

While undertaking these business improvement initiatives, Malwatte Valley has also stepped up its commitment to the environment as well as to its employees.

As part of its solar energy adoption initiative, the company has thus far installed 330KW of solar energy, reducing its carbon footprint by approximately 330 MTCO2e per year – approximately equivalent to the annual average emissions of 72 passenger vehicles. In addition, the company also has obtained several international certifications relating to environmental protection and sustainability including Rainforest Alliance.

In terms of commitment to workers, Malwatte Valley Plantations’ outreach initiatives make a measurable and tangible impact on the lives of its employees, as the company distributes 5% of its profits directly in cash among its employees on estates. The company has thus far shared profits of more than Rs. 150 million with its employees since 2007.