Friday Feb 20, 2026

Friday Feb 20, 2026

Monday, 26 February 2024 19:04 - - {{hitsCtrl.values.hits}}

|

Anunine Holdings Chairman Deshamanya Anurath Abeyratne |

|

Intelligent Harvesting Technologies Ltd. (IHT) unveils its latest, urgently needed innovation – the Automated Rubber Harvesting Robot, which is set to address a serious concern in Sri Lanka’s declining rubber industry.

Perilous state of Sri Lanka’s rubber industry

Since 1876, the Sri Lankan rubber industry has been deeply rooted in the cultivation of rubber trees and the meticulous processing of latex into various products such as tires and gloves and has been known for its worldwide quality recognition.

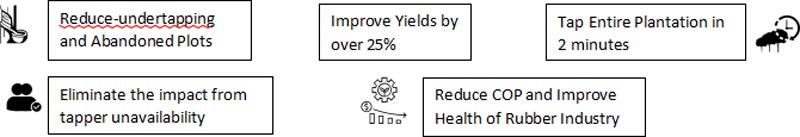

However, the industry faces dire challenges, especially the drastic declining availability of skilled tappers and the lack of protection from adverse weather conditions. This shortage has led to severe under-tapping and the abandonment of plots, plummeting the rubber output in the country. From 150,000 metric tons (MT) in 2012, Sri Lanka’s rubber output sharply dropped - to below 70,000 MT in 2023.

When examining yield per hectare, Sri Lanka’s performance in 2022 stands at 679 kg/ha, contrasting with other leading rubber-producing nations – Thailand achieved 1,469 kg/ha in 2018, while India reached 1,459 kg/ha in 2020. In 2021, Sri Lanka dropped to an alarmingly low 17th position globally in total rubber production. This has led to the rubber industry facing a perilous concern which has yet to be resolved.

Urgent challenges in the rubber industry

“Imagine a rubber plantation owner, faced with the daunting task of ensuring a bountiful harvest. For years, this owner has now helplessly watched the decline in skilled workers available for tapping rubber trees. Ultimately giving up and abandoning their plots as there is no one to tap their trees. This has led to our acreage of rubber plantation dropping to 98,00Ha from 140,000Ha in just the last two years. There are mainly two contributing factors for decline in rubber output and yield - the decreasing availability of skilled tappers which lead to under-tapping and complete abandoning of plots, as well as the increased rain days and lack of rain protected harvesting. These are the two challenges that we seek to take on with this groundbreaking harvesting system,” stated Anunine Holdings Chairman Deshamanya Anurath Abeyratne.

Addressing challenges with innovation – empowering farmers, creating jobs

“Recognising the pressing need for change, IHT introduced the Automated Rubber Harvesting Robot. This cutting-edge technology aims to revolutionise rubber tapping by completely automating the tapping process, thereby eliminating the industry’s dependency on skilled tappers and ensuring the stability and reliability of the rubber industry. The harvesting activity will now require only unskilled labour to collect the harvest, after the robot has harvested the tree. Instead of displacing jobs, the robot complements the work of manual labourers, filling the massive gap left by the shortage of skilled tappers while creating new job avenues due to the increased production and the establishment of regional service centres by IHT,” stated Anunine Holdings Group Director Saveen Abeyratne.

Automated Rubber Harvesting Robot – the solution for the shortage of skilled tappers

The robotic harvesting system is an integrated solution wirelessly connecting over hundreds of thousands of rubber harvesting robots, each occupying a single tree and controlled remotely through a desktop or mobile application. Each robot is configured to follow a harvesting schedule, tapping its host tree every day or every other day at any specific time whether day or night, without any human intervention as it follows a planned schedule.

IHT states that increased yields of over 20-30% can be expected by harvesting the tree regularly, and in the early hours around 2-4 a.m., which also means that collectors can start the day by collecting and move on to another task, thus optimising their work day. The solution is designed to overcome common concerns such as uneven barks or slanted trees, a long lifetime of over 10 years, as well as maintaining a low and adjustable bark consumption of 1.6 mm per cut.

Further to this, the robot does not have a limitation on the height it operates unlike human tappers, possibly extending the useful lifetime of the tree beyond 35 years. Advanced features like automatic water removal ensures no contamination of left over water mixing with the latex. As the robots work simultaneously, the entire plantation is harvested in under 2 minutes!

Plans are underway to establish local and regional service centres creating job opportunities, while providing technical support to all plantations and small holders that use this harvesting robot.

Rain protection

A primary concern – rain protection has decisively been addressed, with a rain-guard being part and parcel of this innovative system, to ensure uninterrupted tapping and maximum yield. Increasing the tapping days by over 80 days, bringing the total tapping days to over 260 days per year with no interruptions due to unavailability of skilled labour.

Benefits for Sri Lanka and the rubber industry

The introduction of this revolutionary technology brings forth a multitude of benefits for Sri Lanka and its rubber industry. Firstly, this revolution in rubber modernisation will have a long-lasting impact on the rubber farmers and small holders who are giving up and abandoning their estates passed down from generations as they are helpless without skilled labour. With this harvesting system they can generate significant and steady profits from their estates, and regain the interest of their youth as the rubber industry will transform from manual and labour heavy operation to one that is embracing technology, automation, data whilst generating steady incomes with less hassle.

Secondly, by drastically improving the yield and production output from existing rubber plantations, the need for importing rubber can be reduced, helping save forex whilst giving value added exporters a steady, and reliable local supply of rubber for their industries to remain competitive in the global market. Currently Sri Lanka serves as the world’s hub for solid tyres, producing over 52% of the global requirement, with FDI’s investments being made into Sri Lanka by MNCs. The stable and sufficient supply of local rubber through this technology will ensure Sri Lanka remains an attractive base for future FDIs and also benefit from greater tax revenues and forex inflow from increased exporter performance.

With reduced labour costs of over 40%, reduced under tapping and abandoned plots, the entire industry from farmers to plantation companies, the value-added exporters and the Government can enjoy the benefits of optimal productivity and increased revenues – ultimately regaining Sri Lanka’s position as top ranked rubber producing nation, and one that is at the forefront of embracing technological advancement.

Partnering for progress

The Automated Rubber Harvesting Robot is the result of extensive research and development by IHT in collaboration with a leading Chinese technology company. With over a decade of experience and numerous patents to their name, the partners are committed to localising the technology to suit the Sri Lankan context, ensuring its effectiveness and relevance. With the support of local institutions such as the Rubber Research Institute of Sri Lanka, IHT plans to expedite the localisation process through industry trials and formalised research in the coming months.

Looking to the future

As the world transitions towards automation and sustainable, carbon neutral practices, Sri Lanka stands poised to embrace this transformative technology. With its early adoption of the Automated Rubber Harvesting Robot, the country can lead the way in revolutionising agricultural practices and ensuring the long-term viability of its rubber industry.

Innovation lies at the heart of progress, and with the introduction of the Automated Rubber Harvesting Robot, IHT Ltd. paves the way for a brighter future for Sri Lanka’s rubber industry. By harnessing the power of technology, the company empowers farmers, enhances productivity, and secures the sustainability of one of the nation’s most vital sectors. As Sri Lanka embarks on this journey of transformation, the possibilities are endless, and the potential for growth is limitless.