Wednesday Feb 18, 2026

Wednesday Feb 18, 2026

Wednesday, 29 September 2021 00:00 - - {{hitsCtrl.values.hits}}

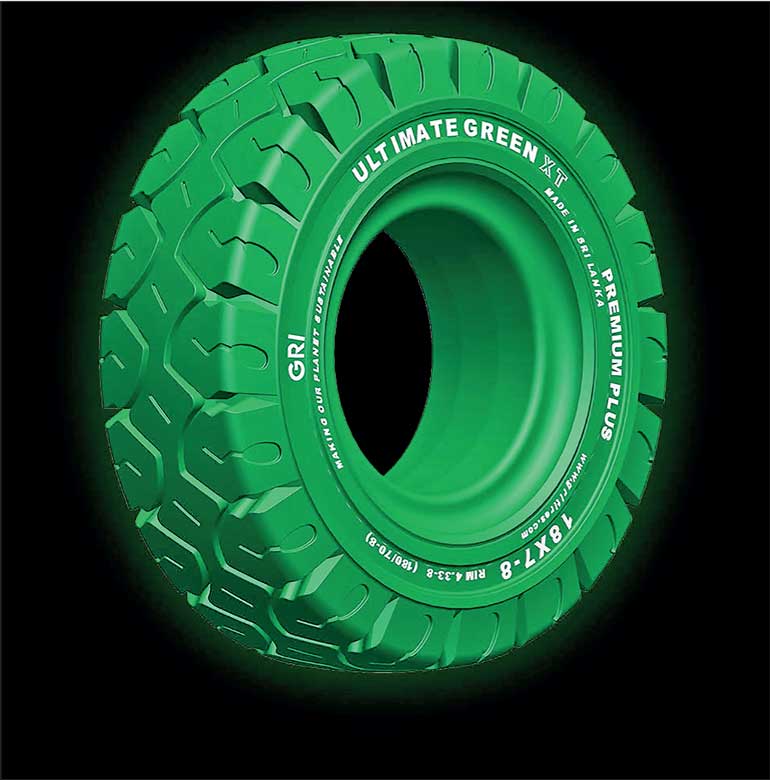

GRI has reaffirmed its commitment to protecting the planet by launching ‘Ultimate Green XT,’ which it said is one of the most environmentally-friendly material handling solid tyres in the world.

GRI has reaffirmed its commitment to protecting the planet by launching ‘Ultimate Green XT,’ which it said is one of the most environmentally-friendly material handling solid tyres in the world.

“Environmentally sustainable growth is our strategy today and for generations to come. We work towards this goal through the way we produce our tyres as well as develop new tyres. The Ultimate Green XT solid tyre for the material handling industry is a result of our drive to create and manufacture products that are sustainable,” explained GRI Chief Executive Officer Dr. Mahesha Ranasoma.

The Ultimate Green XT contains 42.8% sustainable materials, which include bio-sourced, and recycled materials. The tyre is built with pure natural rubber, silica, recycled carbon black, and reclaimed rubber from used tyres.

This novel tyre provides a higher energy efficiency due to its 20.4% lower rolling resistance than the current tyre. Therefore, using the Ultimate Green XT tyre will result in higher energy saving whether it is an electric forklift or internal combustion engine forklift. Furthermore, this new solid tyre also provides higher lifetime as it has 26.6% lower abrasion loss.

The Ultimate Green XT is a premium-plus material handling tyre, built for 24 hours per day, three shift operations, enabled by lower heat build-up and higher endurance. The green colour version is a non-marking, high-performance tyre developed for all surface conditions and intense operating environments.

“In creating the pioneering Ultimate Green XT, we not only considered environmental protection by using a high degree of sustainable materials, but we also focused on improving performance such as increasing energy saving of forklifts as well as extending the lifetime of the tyre. With innovations such as this, we strive to inspire our industry towards making a positive impact on our planet,” GRI Managing Director Prabhash Subasinghe said.

The tread compound of the non-marking Ultimate Green XT contains highly dispersible silica and no carbon black, lowering abrasion loss, and thereby reducing particle release into the environment. In the centre and base of the tyre, GRI has used recycled carbon black. Natural oil is used instead of petroleum-based oil and GRI has pioneered the use of carbon nanotubes in the black version of the tyre.

“Ultimate Green XT goes beyond the norm to deliver the ultimate in sustainability, performance, and efficiency. It was developed over two years and tested rigorously. Powerful and robust, this tyre epitomises GRI’s advanced engineering, research, development, and manufacturing capabilities,” explained Dr. Ranasoma.

"As a responsible organisation, we have aligned our activities with the UN Sustainable Development Goals of Climate Action, Responsible Consumption & Production, Life on Land, and Affordable & Clean Energy. The Ultimate Green XT has been developed in line with these goals and our unique Green X Circle, thus reiterating GRI’s commitment to sustainability," he added.

“I am extremely proud of GRI for having invented such a visionary and innovative solid tyre for its customers. It’s a first on many fronts for the company, the country and the world,” GRI Chairman Harris Premaratne said.

GRI produces high-grade specialty tyres that are built sustainably using pure natural rubber in Sri Lanka. Founded in 2002, the company produces material handling solid tyres, radial agriculture tyres, and construction tyres. GRI has operations in nine countries, and a business presence in over 50 countries worldwide.

Since 2018, GRI has been advancing in the rapid expansion of its specialty tyre production plant and compound mixing facility in Sri Lanka as well as its businesses internationally. GRI ensures its commitment to sustainability and environmental protection throughout its operations locally and globally.