Tuesday Feb 03, 2026

Tuesday Feb 03, 2026

Wednesday, 15 March 2017 00:00 - - {{hitsCtrl.values.hits}}

Text and Pix by Harsha Udayakantha Peiris

Text and Pix by Harsha Udayakantha Peiris

“Four-year-old children in Korea today are learning programming and coding on soft platforms. The region today is focusing towards a state-of-the-art innovative industry revolution and therefore Smart Industry through the 4th Industry Revolution, now known as Industry 4.0 should be well understood by all regional economies geared to achieve their expedited goals of economic development,” says David Sehyeon Baek, Chief of International Affairs Cooperation and Public Relations of Gyeonggi Center for Creative Economy and Innovation in Korea.

He made these statements addressing a session at the Multicountry Observational Study Mission for Mass Media Practitioners on Innovation and Productivity Promotion for SMEs organised by the Asian Productivity Organization (APO) and held recently in Japan. Eighteen participants from across Asia-Pacific, including two representatives from Sri Lanka, attended the programme.

The expert points out that the industry revolution that took place in its first stage through mechanisation and also converting resources such as water power to steam power was brought forward towards a second stage via segments such as mass production, assembly lines and utilisation of electricity to a greater extent which was then furthered through a third stage for industries to become computer related automation and at present, to a fourth stage across cyber physical systems.

The 4th Industry Revolution reaches in three main stages namely, ‘Smart’ where the machine learns himself, ‘Network’ where all connect through sensors and ‘Autonomy’ where the machine performs without waiting for human orders.

Artificial Intelligence or ‘AI’ is the core mechanism utilised in the fast approaching 4th Industry Revolution. ‘AI’ is the simulation of human intelligence processes by machines, especially computer systems. These processes include learning which is the acquisition of information and rules for using the information, reasoning which is using the rules to reach approximate or definite conclusions and self-correction. Here, the machine learning will reach a deep learning at the latter stages. Once machine learning begins to flourish through ‘AI’ and Internet of Things (IOT), deep learning breakthroughs will drive an ‘AI’ boom.

Autonomous vehicles with video cameras, radar, lidar which is a rotating sensor on the roof that scans 200ft in all directions to create a 3D map of its surroundings and position estimator which is a sensor on the left rear wheel that measures the car’s movements so that its position can be mapped with accuracy will soon be on the roads of cities showing their capability of sensing its environment and navigating without human input.

Another fast approaching innovative technology in the 4th Industry Revolution is the 3D printing which is capable of 3D printing of human organs to factory and industry products.

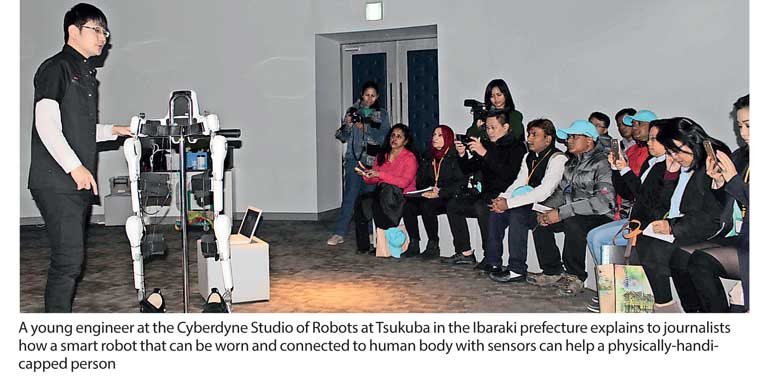

At the Cyberdyne Studio of Robots at Tsukuba in the Ibaraki prefecture, smart robots that could be worn and connected to human body with sensors are produced to help masses of people with physical disabilities and temporary paralysis. Utilising the innovations and best practices of the 4th Industry Revolution, at present, they are hiring these smart robots at various medication facilities, hospitals as well as airports for medical and hard labour requirements.

Future farms will be small and smart. Vast quantities of rich and varied data generated by a farm will be stored in clouds. Such data can be used as digital evidence reducing time spent completing grant applications or carrying out farm inspections saving huge costs of finances lost per farm per year. Areal drones will survey the fields, mapping weeds, yield and soil variation. This enables precise application of inputs and mapping spread of pernicious weeds that could increase yield by 2-5%.

Sensors attached to livestock in the farm will allow monitoring of animal health and wellbeing. They can send texts to alert farmers when a cow goes into labour or develops infection increasing herd survival and increasing milk yields by 10%. Smart tractors with GPS controlled steering and optimised rout planning will reduce soil erosion saving fuel costs by 10%.

A fleet of specialised robots called agri-bots will tend to crops, weeding, fertilising and harvesting. Robots capable of microdot application of fertiliser will also reduce fertiliser costs by 99.9%. This will also greatly minimise health hazards from chemical fertilisers to farmers and consumers of agriculture produce.

Mihai Andrei, a journalist reporting in ZME Science, had recently stated that after a factory in Dongguan in China replaced most of its workers with robots, it witnessed a spectacular rise in productivity.

“It’s been long discussed that robots and computers will start taking our jobs in the near future which we are really not prepared to deal with. Of course, some jobs are more at risk than others. According to Monetary Watch the Changying Precision Technology Company that engages in the production of mobile phones and uses automated production lines has dropped their human work force from 650 to 60, while robots take care of the rest. In time to come, the number of required employees will drop to 20 at one point. Despite this reduction in staff, not only is the factory producing more equipment, risen to a remarkable 250% increase, but it is also ensuring better quality,” Andrei had reported.

According to Oxford University, almost 47% of the current jobs that also include utility company engineers, delivery and taxi drivers, some teachers, travel agents, air traffic controllers and pilots, book keepers and accountants, interpreters and translators as well as newspaper reporters will disappear in the next 25 years.

“But at the same time, new jobs will also arise under 4th Industry Revolution, says David Sehyeon Baek, Chief of International Affairs Cooperation and Public Relations of Gyeonggi Center for Creative Economy and Innovation in Korea.

“So, with the arrival of the 4th Industry revolution, everything from home kitchen to factories, laboratories, cities and fields will be smart. Therefore, the governments and institutions who take initiatives to train their HR have to newly think of any such emerging opportunities. 4th Industry revolution should not be considered rival that limits, filters, steals resources and competencies or stops skilled migration in developing countries. So, it is important that developing nations should think of possible allied conglomerations or collaborations with developed industrial nations in such contexts rather than thinking developed industrial economies as rival threats. And we should also remember that no conglomerate is sustainable unless it is innovative as we need more innovative and diversified businesses at present to emerge as success nations to better feed the world infuture,” Baek says.