Friday Feb 20, 2026

Friday Feb 20, 2026

Tuesday, 23 August 2016 00:12 - - {{hitsCtrl.values.hits}}

By Shannine Daniel

Sri Lanka’s plastics industry needs to reduce the amount of energy consumed in the hope of reducing costs, stated Tangram Technologies Ltd. Managing Director Dr. Robin Kent, as more than Rs. 5.1 billion is invested per year by the industry on energy alone.

Speaking at the ‘Plastics Save’ CEO Forum and Seminar organised recently by the Plastics Industry Association of Sri Lanka (PIASL), Kent said that the Sri Lankan plastics industry emits 127, 000 tons of carbon into the environment and if the amount of energy consumed by the industry is reduced, adverse impacts on the environment could also be reduced.

The plastics industry as a whole has been getting a lot of negative attention over the past few years and pressures have arisen due to environmental pollution, global warming and other related issues. In the interest of being green, Kent asserted that it is not impossible to be productive and efficient at the same time. He highlighted the importance of reducing the consumption of energy as the main procedure.

He added that finding out which process consumes the most amount of energy was one of the significant factors which needed to be considered to avoid the excess consumption of energy. In order to do so measuring key data such as Energy used, production volume and operating hours need to be measured and recorded.

In terms of manufacturing Kent stated that manufacturing and the impact it generates are not separate processes; they are integral in reducing costs and environmental impact.

He went on to say that manufacturing needs to be considered as a part of the sustainable process. He added that targeting actions to reduce the cost of materials as well as targeting actions to reduce the costs of controllable overheads are important steps which have to be considered.

“We think energy is a fixed cost but it is not; it is a controllable overhead. Energy costs and carbon emissions can be reduced by up to 30%,” Kent asserted.

Pros and cons of renewable energy resources

In Sri Lanka, 56% of total energy consumed is hydropower and biomass, and currently the Government is looking at alternative renewable energy resources within the country such as solar power and wind power since the country can no longer depend on hydropower or fossil fuels.

Worldwide there is a general move towards renewable energy resources but this is a complex move, Kent told the Daily FT. Renewables are not always reliable sources of energy; they are not effective when there is no sunlight or wind available and therefore hydro power stations and power stations that derive energy from non-renewables may still need to function to ensure that there is sufficient energy to run the industry, he revealed.

“However, if used correctly, renewables can take the daytime load and save water for the night time load,” he said.

Another disadvantage that Kent noted in using renewable energy sources is the cost of implementation, however he also added that using renewables as energy sources would be beneficial in reducing the carbon intensity, and therefore the carbon footprint of the country.

Labour and resource efficiency

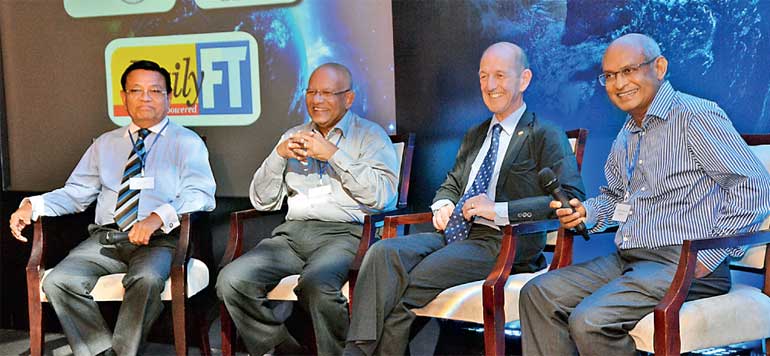

From left: Panelists CEI Plastics Ltd Director Anver Dole, Kelani Cables CEO Mahinda Saranapala, Tangram Technology Ltd., Managing Director Dr. Robin Kent and moderator. Dr. Kamal Weerapperuma

Touching on the subject of labour, he stated: “It is important to keep the labour whilst sacking the kilograms and the kilowatt hours. Especially in an economy like Sri Lanka where the costs of labour are relatively low, it is important to focus on increasing the labour and bringing the kilowatt hours down.”

“We need to think about the consumables as well; Sri Lanka is more fortunate than many other parts of the world such as the Middle East where water is extraordinarily expense and much thought needs to be given to consumables such as these,” Kent further stressed.

Kent further highlighted the importance of improving resource efficiency in the plastic industry, stating that 80% of plastic products are discarded after single use. He further stated that resource efficiency needs to be improved in other industries as well since 99% of the product materials are discarded within six weeks and 93% of production materials do not end up as saleable products.

Recycle, reuse and reduce

In order to be more resource efficient and reduce the use of consumables, Kent emphasised on the concept of “design for use” as an important factor that has to be considered as some products use more energy and resources when they are utilised than in the manufacturing process. He noted that ‘sustainable design’ is an imperative part of the design process.

Disposal is another factor which needs to be considered in the production of plastics, stated Kent. Disposal is becoming increasingly expensive at the end of the life of a product and in future producers will become responsible for the costs generated, he added.

Therefore Kent expressed the need to consider important factors such as sustainability and recycling, to avoid adverse environment impacts. Kent highlighted the importance of designing products without the use of hazardous materials and products that can be recycled or reused to reduce social costs. “Recycled raw materials are cheaper and more energy efficient,” he said.

Furthermore Kent also stated that the concept of recycling, not only with plastics but other non-degradable as well, needs to be given more awareness in Sri Lanka. Measures also need to be taken to improve the relevant infrastructure, so that people will have more incentive to recycle instead of carelessly dumping these products in their surroundings and therefore reduce the amount of pollution in the country.

Sri Lanka’s plastic industry

Considering Sri Lanka’s plastic industry Kent told the Daily FT that the industry had potential, the people involved in the industry that he encountered were skilled, enthusiastic, knowledgeable and motivated, and their equipment was of a good standard.

“I think Sri Lanka has great technical people who can contribute to developing the industry. The industry is as good as anywhere in Asia and the language skills of the staff are very good in terms of bringing in new technology. From what I have seen the energy saving equipment that is being used is either state-of-the-art or nearly state-of-the-art,” he revealed.

The real downside of the industry, acknowledged Kent, is the size of the ‘home’ market – this is small and does not give the industry a chance to develop the necessary critical mass of companies and technology.

“If trade barriers come down, then this could either threaten the industry or make it much stronger,” Kent stressed.

He went on to say that due to increased globalisation the country needs to become more competitive on a global scale. “Now we have to think of the world as our competitor; there is no local market as such now. Competitors are all around the world, countries such as Malaysia, Thailand and Vietnam,” he stated.

Pix by Upul Abayasekera