Tuesday Feb 17, 2026

Tuesday Feb 17, 2026

Monday, 7 December 2020 00:00 - - {{hitsCtrl.values.hits}}

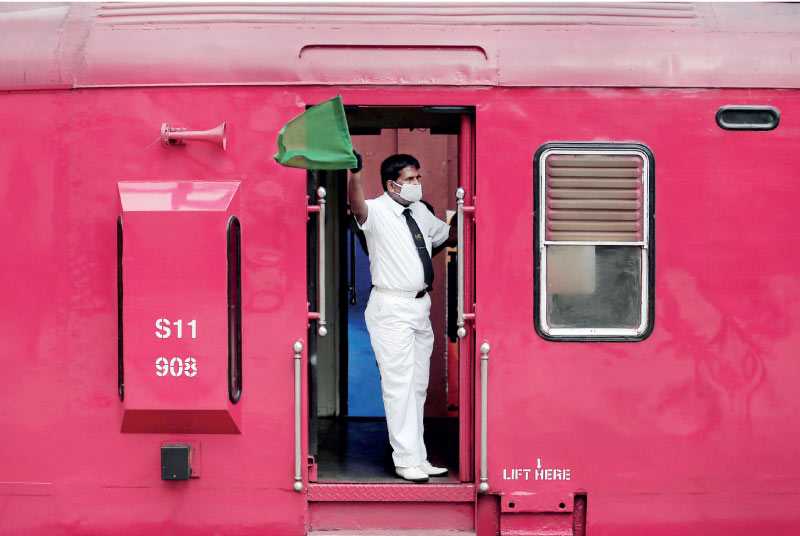

The Sri Lanka Railway Department has to rethink its strategy on adding significant value to Sri Lanka’s economy – Pic by Shehan Gunasekara

By K. Jayaratna

I joined the Sri Lanka Railways Department back in 1969 as an apprentice, and retired after 45 years of service. Sri Lanka Railways consists of five sub-departments, out of which I was selected to work in the ‘Permanent Way’ division of the Way & Works sub-department through a very competitive interview process.

The division I worked in, ‘Permanent Way’ embodies what railway is about – that it is a permanently fixed pathway on which a train operator would operate the locomotive. The locomotive operator does not have to take any decisions other than on the speed of the train and the stops in terms of manoeuvring the vehicle.

In almost all countries, the Way & Works Department is treated as the heart and soul of Railways, if you take the UK, the rail lines are maintained by the government with private operators running services on it. The speed of the train, the type of locomotives, the comfort of the passengers as well as the safety of them all depend on the quality of the railway track, or the permanent way. In Sri Lanka, the Way & Works Department does not have any special recognition and is treated at the same level as the other sub-departments.

The translation to Sinhala and Tamil of railway is also incorrect. In Sinhala it is referred to as ‘dhumriya,’ which when translated back to English means ‘Smoke (dhum) Chariot (riya)’ giving a completely different meaning of Railway to our daily vocabulary and prominence to the locomotives and coaches that operate on the rail track.

The term ‘dhumriya’ was used to describe coal-fired steam engines used during the colonial rule and it is now only used for ceremonial purposes or special chartered trains such as the Viceroy. Modern day trains used diesel or electric locomotives. Therefore from the name itself the Sri Lanka Railway Department has to rethink its strategy on adding significant value to Sri Lanka’s economy.

Trains are the best way to transport large amounts of people and goods in the most economical manner – one example is how agri produce is transported across the island. Ideally the Sri Lanka Railway Department should be rebranded as ‘Sthira Marga Departhamenthuwa’ to communicate its true nature and service.

My apprenticeship period covered main disciplines including railway track, drawing office, survey department, permanent way workshop, mechanical engineering and signal systems. Upon successfully completing the training period I was appointed as Inspector Permanent Way – II, which is working as the assistant for the Inspector Permanent Way – I.

After a few years I got promoted to Inspector Permanent Way – I, whose responsibilities include maintaining circa 30 miles of track for smooth train operations. The maintenance involves about 100 strong labour force and heavy machinery and involves regular maintenance as well as emergency repairs in the event of a breakdown.

Developing and maintaining a track includes many aspects, from building a solid formation for the track to be steady at high speeds, to road crossings (called level crossings), track change points, bridges, culverts and tunnels.

The Railway Department owns a large portion of land on the sides of the track, these are allocated for future expansion of services – however there has been little money invested by successive governments to strategically develop the railway network across the island. The reconstruction of the track to Jaffna was a significant achievement and a much-needed one, however there is a lot more that can be done to benefit the economy in a significant manner.

One of the challenges I had to face was not maintaining the track but ensuring the land that belongs to the department was not illegally occupied. I have had many instances of having to deal with encroachment where we have to take swift action to prevent permanent fixtures getting setup. We also had to deal with earth slips and washaways during the rainy season, which was always a tough situation to handle as you had to repair the track while being in danger of further earth slips – the repairs were usually done during heavy rain in order to get the trains back in operation.

My job had a Human Resources side to it as well, handling the 100-strong labour force was no easy task but one I enjoyed, as without them we couldn’t have done what we did – where most of our work was done manually.

2009 tsunami and the restoration of the Eastern Line

I have had many memorable experiences working in Sri Lanka Railways but the one that stands out is relaying the east coast Batticaloa Line in 90 days, after it was washed away by the devastating 2009 tsunami.

By that time, I was the Chief Inspector of the Permanent Way, which expanded by responsibilities to cover half a district. As the Chief Inspector for the Batticaloa Line, I was in charge of the track between Gal-Oya Junction and Batticaloa. The world’s attention was drawn towards the disaster that struck the Matara Express train, where 1,700 innocent lives were lost and is considered as one of the biggest train disasters in the world. The destruction caused by the tsunami to the Eastern Line track was similar to the one in the Southern Line and fortunately we did not have any fatalities as trains were not operating at the time the tsunami struck.

Our District Engineer S.G. Bandara, myself and other officers got together to swiftly relay the damaged track. It was not an easy task; some parts of the railway track were found on top of palmyrah trees with rails and sleepers. We had wooden sleepers on this track and some were damaged beyond use, while culverts were washed away completely.

We started the work and filled the washed away area by filling sand and earth from either side of the track. The rail tracks that were stuck on top of palmyrah trees were bought down and carried over to the area the rail track was and in some instances these were found about a quarter mile away from the rail track.

We did not have any heavy machinery to support our work, not even a backhoe, and it was done manually by the labour force from digging earth to create the track formation to bringing down the rail tracks from the palmyrah trees and carrying them over to their original location. The only equipment we had was a locomotive engine and five compartments which we used to rest in during the night and to prepare our meals.

Our daily routine started at 7 a.m. and ended till daylight ended which was usually around 5:30 p.m. on the east coast. Even the material to fix the rail track was unavailable and there was no method to bring any material from Colombo. At that stage the county was in a state of shock and chaos where the Government’s main focus was providing relief to those displaced and rightly so.

We restored the track with the rails and sleepers we had to enable transportation of material from Colombo. Thereafter with the material we got, we certified the track to operate at a cautious speed of 5mph for commuter transport. This is significantly lower than the usual speed and the reason for the cautious speed was because the track was not strengthened to operate at high speeds. Our main objective was to get services operational as soon as possible to enable commuter and goods transportation.

All this work was completed within 90 days with very limited resources and it was a tremendous effort by my entire team. All the staff were commended by the then General Manager Railway Priyal De Silva.

Improving the Kelani Valley Service

As a retired person at the age of 72 years, having a little sickness, I still think about my Railway career with fond memories. I have seen discussions happening with the President on the LRT (Light Rail Transit) and related to that on improving the Kelani Valley (KV) rail track. I thought about this and came up with some ideas on how to further improve the proposal for the KV line which is right now focused on improving the maximum speed of the track.

The speed of a track depends on many factors. The formation of the track, that is the base on which the track is laid, should be very solid and is usually about one feet thick. Another factor is welding of rails to minimise gaps. When travelling in trains you may have noticed a rhythmic noise, which happens when the wheels hit the gap between two rails. These gaps do not give a smooth ride to the passenger and affects the train speed. I have welded rail lines up to a quarter of a mile on the Puttalam Line, which was not the recommendation, and even today trains operate on that line without any problem.

The other factors that contribute towards the speed are the bends and the angle of the track at these bends to maintain the speed as well as clearance of the track with the assurance to the locomotive operator that there will not be any people or animal crossing the line other than at designated crossings where the rail line meets the road.

While improving the speed of the existing single line KV service is a very good initiative, we can do more. It is possible to lay a double line on the existing track formation itself without having the expand/acquire land by using ‘Meter Gauge (MG)’ line. This idea actually occurred to me at 2 a.m., when I was up for some reason – sometimes the best ideas occur at the strangest of times, I thought.

Most countries use MG railway lines where the compartment size is roughly the same with similar capacity to a ‘Broad Gauge (BG)’. Sri Lanka currently uses BG lines. A MG line will require new locomotives and compartments but I believe the benefits outweigh the cost of the project.

By having a double line we will be able to provide a more frequent service at peak times to transport passengers quickly. In the event of a breakdown of service on one line due to a derailment or a track repair, we can still operate a good service for commuters using the available line. If in the future we decide to invest in a project similar to the LRT, which was built on MG, the same train service can then operate on the KV Line without having to build expensive transit hubs for passengers to switch from the LRT to KV. Any investment to buy locomotive for MG width can be used for a future LRT type service.

How would we go about expanding the KV service?

If in principle this is seen as a benefit to the commuters and the economy, we should do a study on the cost of this project and compare that to the existing KV Line improvement proposal. While the cost may be slightly higher, I am certain a cost benefit analysis would prove a double line will have a greater impact on the long term. I have given below a simple plan on how to go about expanding the KV Line and also key points where we need to keep provision for future expansion.

1.Concrete sleepers we use for the railway lines are locally manufactured at the Maligawatte Concrete Sleeper Factory. Sleepers required for the MG track can be built here.

2. The train service between Avissawella and Waga needs to be closed and replaced by a dedicated bus service, which commuters can use with the same train ticket. This is the usual practice in any country.

3. The MG line can be then laid between Avissawella and Waga and the existing Yard at Avissawella should be dismantled. Recovered sleepers and rails should be transported to Colombo for reuse of the BG lines elsewhere.

4. When laying the new MG track, we should remove about one foot depth of earth under track and introduce coal dust, tamp it to strengthen the bed of the track. Coal dust can absorb more water during rainy weather and evaporate easily with sunlight.

5. The Avissawella Yard should be redesigned considering requirements of future generations where it can be expanded to provide more services. A yard is a place where locomotives and compartments are parked and trains start services from the yard.

6. As the population grows future generations may require to extend the double line to Ratnapura-Opanayaka and even beyond that all the way to Nuwara Eliya. Therefore the Avissawella Yard will become very important in maintaining and repairing locomotives, compartments and any renewals of engines. The other key factor is that since these trains are MG width, they cannot be taken to Ratmalana for any repairs. Therefore the workshop at Avissawella should be complete enough to service the KV Line MG locomotives and compartments. For this purpose there is a railway land called ‘Gravel Siding’ which was earlier used to cut gravel for the KV Line to ballast the track. The Avissawella Yard should provide tracks to travel to this newly-built workshop. In the future when the track is extended to Ratnapura we should have another workshop at Ratnapura for this same purpose.

7. We first start building from the Avissawella Yard and at the start manual labour will be used to trolley concrete sleepers, rails and components to the site. These materials should be transported from Colombo by lorry. The Way & Works Department should purchase a few lorries and should be given to other Government departments and we repurpose the old lorries of those departments for this project. Purchasing a lorry is more profitable than renting.

8. When laying the Avissawella Yard we should import a loco and BLSS wagons (for sleeper and material transport) and two TVVs (Guard Room). This is to transport material from the Avissawella Yard along the newly-laid track, in order to build the track. Once the track is laid up to Waga, passenger transport can be conducted and we should import a powerset with a few coaches in advance while the track is being laid.

9. After laying tracks (up and down) between Avissawella and Waga we should close down BG train traffic between Waga and Morakele similar to how we did it between Avissawella and Waga.

10. Similar to before passengers should be provided transportation services using dedicated buses between these two points.

11. With this method we can lay the track all the way up to Maradana.

12. Whenever there is a need to cross roads with heavy road traffic, we should lay overhead bridges for the road traffic.

13. There should be crossover tracks wherever required and it should be decided by Way & Works engineers.

14. Colour light system should be done by STE (Signal and Telecommunication Engineer) Department.

15. When track laying is in progress we should import more power sets, locos and wagons for the use of Way & Works Department and Locomotive Department.

16. Strengthening of track by using ballast should be done with the progress of the work.

17. Station and other passenger requirements should be planned by the Transportation Department.

18. With the completion of laying of track all encroachment should be removed and a fencing should be done to prevent anyone from crossing the track. By fencing the train can proceed at maximum speed without having to operate at cautious speed.

This is a brief idea of how to lay a double line meter gauge track between Avissawella and Maradana. We should appoint a suitable committee to prepare a suitable arrangement do this work and bring it to the attention of President Gotabaya Rajapaksa.

A few further notes

(The writer is a retired Chief Inspector Permanent Way, Sri Lanka Railways, and can be reached via email [email protected])