Thursday Feb 19, 2026

Thursday Feb 19, 2026

Friday, 3 September 2021 00:00 - - {{hitsCtrl.values.hits}}

Biodiesel powered tractor in Sri Lanka

|

Macro level biodiesel plant |

|

Domestic biodiesel plant

|

Current background

Budget deficit and import substitution are common words in the Sri Lankan jargon during this time. Fuel import is an inelastic demand that non-petroleum-producing countries are facing. Alternative sources of energy and renewable energy are on the verge. Biodiesel will be a decisive component in the Sri Lankan commercial sector since most of the cargo-related modes are operating more on diesel than petrol.

Petrol hikes do not affect much when compared to diesel in the commercial sector. Therefore, keeping the cargo business intact, the most viable option would be having biodiesel as the substitute. It has been tested and found by the Coconut Research Institute in Sri Lanka that 40% of biodiesel can be mixed with fossil diesel. What is most attractive is that biodiesel has three times the energy factor than the common diesel.

Biodiesel can be extracted domestically and the people will not be hesitant to use it. Even at present, people experiment with many other unorthodox ways to substitute diesel. As an example, kerosene oil is mixed with lubricants and used as a fuel for diesel vehicles. Therefore, the end user will not hesitate to apply biodiesel.

Introduction

Energy Symposium 2015 was the eyeopener and change agent of thinking in terms of energy conservation and alternative energy options. Dr. Abdul Kalam was the guest speaker and he delivered the facts of important topics with stunning information. Among them diminishing of fossil fuels, renewable energy, preservation of village concept (Sri Lanka is blessed with 40,000 villages) and the externalities, captured the thinking of the educated audience. He unveiled many alternative energies pertaining to the context of Sri Lanka; wind, hydrogen, thorium, solar and biodiesel were a few of them. Among these, he elaborated much on biodiesel which is in par with the Sri Lankan village wealth and the remarkable efficiency of the source compared to the traditional diesel, and has less pollutants like sulphur and particles.

Biodiesel was not a new concept to Sri Lankan researchers; the Coconut Research Institute

experimented on the subject and demonstrated by driving a hand tractor on biodiesel in the year 2007. Also, it presented a research paper in Kotelawala Defence University International Symposium in 2008 about the commercial advantages of biodiesel in the Sri Lankan concept. The astonishing fact here is neither the Government nor the commercial sector made any attempt to develop and reap the benefits of the source. My attempt here is to publish the summary of the paper that I have produced in the Kotelawala Defence University International Symposium for the public to understand the value and the relevance of the source to the country.

Biodiesel is a very common concept all over the world though Sri Lanka is at a primitive stage as far as the knowledge and application of the biodiesel concept is concerned. Alternative energy is the only scapegoat to the present energy crisis. Therefore, it is important to study about the fruitfulness of biodiesel and apply it to the society and the country. Sri Lanka is blessed with adequate raw materials that can be used as biodiesel. They are kaneru, domba, mee, rubber seeds, etc. Also, people have the knowledge of the industry of these raw materials with the indigenous experience.

Biodiesel has three times more efficiency of fossil fuel diesel when considering the chemical and economic factors. Therefore, it can bring a better impact on the financial sector of the country. The most important factor is the domestic manufacturing of biodiesel and this kind of micro economic industries which give highest productivity to the country. Already, the biodiesel system is tested in the country and this had been developed by the Coconut Research Institute and they have demonstrated driving a vehicle using converted coconut oil biodiesel.

Biodiesel has three times more efficiency of fossil fuel diesel when considering the chemical and economic factors. Therefore, it can bring a better impact on the financial sector of the country. The most important factor is the domestic manufacturing of biodiesel and this kind of micro economic industries which give highest productivity to the country. Already, the biodiesel system is tested in the country and this had been developed by the Coconut Research Institute and they have demonstrated driving a vehicle using converted coconut oil biodiesel.

The main problem in Sri Lanka is the innovations are not integrated with the commercial sector; therefore, the product innovations are dying inside laboratories or take a long time to reach the market. The biodiesel concept needs more integration with the commercial sector, Government and the society in order to improve the economic state of the country.

Historical background

Transesterification of a vegetable oil was conducted as early as 1853 by scientists E. Duffy and J. Patrick, that is many years before the first diesel combustion engine became functional. Rudolf Diesel’s prime model, a single 10 ft (3 m) iron cylinder with a flywheel at its base, ran on its own power for the first time in Germany on 10 August 1893. In remembrance of this event, 10 August has been declared ‘International Biodiesel Day’.

Research into the use of transesterified sunflower oil, and refining it to diesel fuel standards, was initiated in South Africa in 1979. By 1983 the process for producing fuel-quality, engine-tested biodiesel was completed and published internationally. An Austrian company, erected the first biodiesel pilot plant in November 1987, and the first industrial-scale plant in April 1989.

Throughout the 1990s, plants were opened in many European countries, including the Czech Republic, Germany and Sweden. France launched local production of biodiesel fuel (referred to as diester), which is mixed into regular diesel fuel at a level of 5%, and into the diesel fuel used by public transportation at a level of 30%. Renault, Peugeot and other manufacturers have certified truck engines for use with up to that level of partial biodiesel; experiments with 50% biodiesel are underway. In 1998 the Austrian Bio Fuels Institute had identified 21 countries with commercial biodiesel projects. In September 2005 Minnesota became the first US state to mandate that all diesel fuel sold in the state contains part biodiesel, requiring a content of at least 2% biodiesel.

Production and scientific explanation of biodiesel

Chemically, transesterified biodiesel comprises a mix of mono-alkyl esters of long chain fatty acids. The most common form uses methanol to produce methyl esters as it is the cheapest alcohol available, though ethanol can be used to produce an ethyl ester biodiesel and higher alcohols such as isopropanol and butanol have also been used. Using alcohols of higher molecular weights improves the cold flow properties of the resulting ester, at the cost of a less efficient transesterification reaction. After this processing, unlike straight vegetable oil, biodiesel has combustion properties very similar to those of petroleum diesel, and can replace it in most current uses. Biodiesel is more efficient than fossil fuel diesel Cetane value is three times higher than fossil diesel.

Biodiesel feedstock

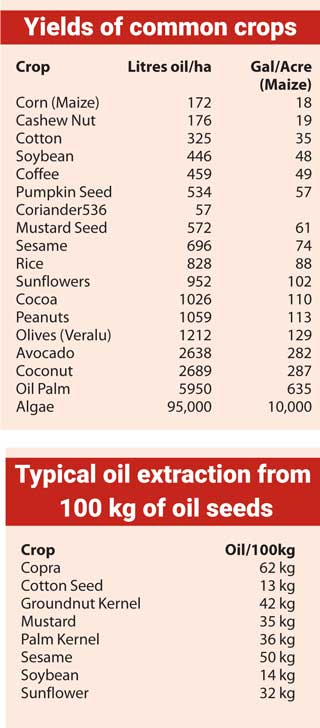

Seeds are used as a source of biodiesel. Apart from that, a variety of oils can be used to produce biodiesel. These include:

Biodiesel feedstock plants utilise photosynthesis to convert solar energy into chemical energy. The stored chemical energy is released when it is burned, therefore plants can offer a sustainable oil source for biodiesel production. Most of the carbon dioxide emitted when burning biodiesel is simply recycling that which was absorbed during plant growth, so the net production of greenhouse gases is small. The highest yield feedstock for biodiesel is algae, which can produce 250 times the amount of oil per acre as soybeans.

Following seeds are abundance in Sri Lanka:

Biodiesel can be extracted basically from any seed that has a kernel. But there are high fat seeds like domba and mee which Sri Lankan people possess the knowledge.

Efficiency of biodiesel and economic arguments

Biodiesel is becoming of interest to companies interested in commercial scale production as well as the more usual home-brew biodiesel user and the user of straight vegetable oil or waste vegetable oil in diesel engines. Homemade biodiesel processors are many and varied. The success of biodiesel home brewing, and micro-economy-of-scale operations, continues to shatter the conventional business myth that large economy-of-scale operations are the most efficient and profitable. It is becoming increasingly apparent that small-scale, localised, low-impact energy keeps more resources and revenue within communities, reduces damage to the environment, and requires less waste management.

Conclusion

Conclusion

The most important factor in Sri Lanka is people have the know-how of the system; scientists have tested and demonstrated, therefore, the requirement of making the conversion devise is the most important factor. This equipment is available in the world market in various capacities from micro industries to macro industries with better economy of scale. At the moment, the most productive industry in the country is the micro level industry or self-employment industry. Therefore, it can be started with a micro level and subsequently developed to macro level with the investor who is in the fuel industry.

But considering the present economic status of the country the micro economic industries are the best because, it eliminates the middlemen process and gives the highest productivity and service to the customer and society as far as rural areas are concerned. The person who possesses the conversion mechanism can supply the seeds for the production and market the product to the customer in the same village since rural areas are based on agricultural economy. There will be a great market from tractor owners and hand tractor owners and other people who need the products. When it comes to macro level it needs better integration of backward process and the customer with the blessings of the Government in order to achieve a better productivity.

Organic manure is the much-discussed topic in the country and subsequently, can achieve the organic status of the country in the near future. The by-product of the biodiesel process can be converted as the organic manure and support the vision of the country while producing biodiesel. Also, it supports to reduce the ambient levels of the environmental pollution due to less hazardous gas emissions like Sulphur.

In 2005, US imposed a law in Minnesota State to add 2% biodiesel to the fossil fuel consumption; likewise, with the present state of seeds available in the country, Sri Lanka too can reduce about 20% fossil fuel imports and secure a greater income to the country. The biodiesel concept is one of the areas which should be known by the people in the country. The Ministry of Energy should launch awareness programs to educate people of the country as far as biodiesel energy is concerned.

The country also can observe that, there are various institutes which conduct researches on alternative energy but nothing gets commercialised due to less integration with the Government sector and the commercial sector of the country. Therefore, eradication of that negative status will give better results too for the implementation of the biodiesel concept in Sri Lanka. Ethically, it is not recommended to source edible food to produce biodiesel, but as I have elaborated, there are plenty of inedible seeds in abundance in the country. Finally, as Dr. Abdul Kalam stated, Sri Lanka can achieve energy security and energy independence through the biodiesel concept.

(The writer is a specialist in Transportation Geography. Presently, he conducts lectures on the subject for Transportation and Logistics Management in CINEC Maritime University. He has published many articles on Transportation and Management. He can be contacted via [email protected].)