Tuesday Feb 17, 2026

Tuesday Feb 17, 2026

Monday, 29 January 2024 00:30 - - {{hitsCtrl.values.hits}}

It is in the interest of the country to take early action to ride this wave by being a collaborative partner of India which is moving fast to make itself a semiconductor country soon

|

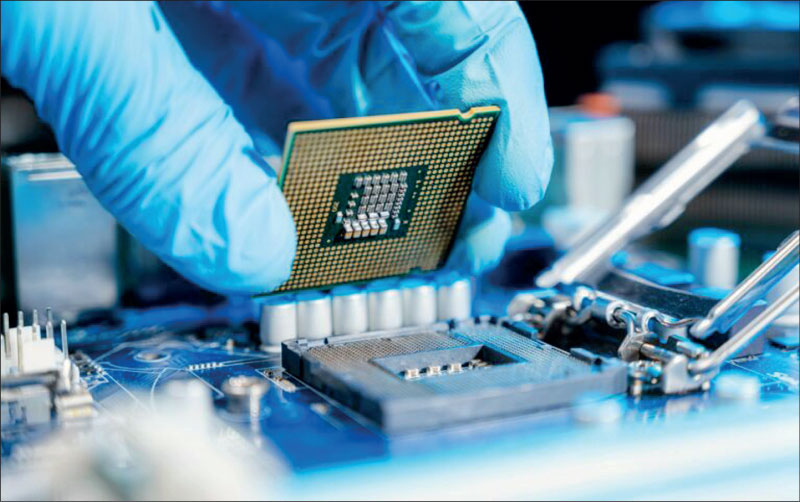

Microchips everywhere

Microchips everywhere

In the last five decades, it was the access to oil or the possession of oil fields that generated prosperity and wealth for a nation. In the next five decades, it will be smart microchips that will do the job. That is because everything from buying a loaf of bread to settling on Mars, all equipment, and weapons that we use will be driven by microchips. Chips are needed by all industries for production, distribution, and consumption, the three main economic activities that we undertake. Take for example a very low level of economic activity like ordering a meal through a food delivery man. From ordering the meal to making payment to taking delivery of the meal on your side are all guided by microchips. From the caterer’s side, taking the order, receipt of payment, and handing the meal to the delivery man are all guided by microchips. From the side of the delivery man, finding the shortest route to accurate address of the recipient to the confirmation of the delivery are guided by microchips. Hence, without microchips, in the modern and emerging digitised world, we cannot think of surviving. It is all over there powering and energising all human activities.

Decade of microchips

According to a report published by the research thinktank, McKinsey Research, 2020s is the decade of semiconductors (available at: https://www.mckinsey.com/industries/semiconductors/our-insights/the-semiconductor-decade-a-trillion-dollar-industry). In 2021, the total value of the semiconductor industry had been close to $ 600 billion, and they have been principally used for computing and data storage and wireless communication. It has been projected that the industry will grow to $ 1 trillion by 2030. In addition to the current users, the motor vehicle industry has been added as a main user of semiconductors. Further, industry, consumer electronics and wired communication have also been identified as users of this precious item.

During the decade, computing and data storage, wireless communication, and automotive electronics will contribute about 70% to the growth. In a fully self-driven car, it has been estimated that about $ 4,000 worth of semiconductors are being used making them an important component in the smart driving system. During 2015-9, the average annual economic profit of the semiconductor industry, namely, the actual profits adjusted for the opportunity cost of capital, has mainly been earned by North American companies ($ 37 billion) followed by Asia-Pacific companies (earning $ 23.4 billion) (available at: https://www.mckinsey.com/industries/semiconductors/our-insights/value-creation-how-can-the-semiconductor-industry-keep-outperforming). In comparison, the European companies earning an annual average economic profit of $ 2.4 billion are yet to make a firm foot stand in the industry.

Collaborative chip makers

Semiconductors are a promising industry and therefore the investors in the industry have high expectations about its growth. If they compete with each other, it will be a ‘lose-lose’ situation. Hence, the chip makers should learn from those who have been successful in creating economic profit. In this case, identifying the profitable segments of the industry and seeking to take leadership in those areas will be the secret to learn. The leading players so far have invested massive amounts in Research and Development or R&D enabling them to come up with improved products and enjoy leadership in the area. The newcomers cannot catch up with them easily. In this connection, McKinsey Research has made three specific recommendations to players in the industry.

Need for partnering

First, they should expand the customer base by partnering with other chip makers across the value chain of the industry. Users need applications that seek to offer solutions to specific problems they have. An example is the applications which banks seek to have for addressing the specific issues faced by customers. For instance, if the internet account of a customer with a bank has been deactivated, there must be safe and quick ways of reactivating the same on a 24 hour into a seven-day basis. Since banks or any other users do not develop their own chips, it is the duty of the chip makers to design such custom-oriented cutting-edge chips. By doing so, they can enter the value chain and capture specific high growth niches. They should also merge with small but well-functioning software developing companies to enhance scales of operations. For that, a specific merger and acquisition or M&A strategy should be developed and put into practice by chip makers.

High alertness

Second, acknowledging that supply chains are continuously evolving, the chip makers should stay alert to such volatilities in the industry. There is a constant diversification of global trade specifically in the case of sophisticated technologies. If they can diversify their own operations, they can count on more than one vendor or supplier at a time. Governments offer generous subsidy schemes, like the present subsidy scheme of $ 52.7 billion offered by the US government (available at: https://www.reuters.com/technology/us-reports-big-interest-52-billion-semiconductor-chips-funding-2023-08-09/) to promote the manufacture of advanced chips which have more secure markets in the globe. Diversification will help them to enter these selected markets. Further, when shortage of chips occurs as in the present shortage experienced by the automotive industry, prices tend to rise. Instead of taking advantage of such price increases, chip makers should fix fair prices on them to facilitate the industry to survive in a collaborative world.

Role of new technologies and innovations

Third, chip makers should adopt new technologies and innovations so that they are always floating above the water. Technology is changing and those who apply new advanced technologies will continue to succeed. This applies to semiconductors currently being produced. If there are faults in chips that are made, the chip maker will lose market confidence and trust. This can be corrected by speeding up the yield learning curve, a technique which involves correcting the existing faults progressively until a manufacturer reaches accuracy at near 100% level. The fault rate in normal manufacturing is six faults per million units produced. However, this is a luxury for chip makers. Imagine a chip fails when an operation is performed by a surgeon using advanced equipment driven by advanced chips. That cannot be tolerated. Hence, the norm for faults in critical chips is zero. This can be attained by chip makers by continuously inventing and innovating.

Division of the world into chip makers and chip users

Because of the importance of semiconductors in critical applications of modern technology and the profit opportunities available, all the leading manufacturing countries are on to the game of producing semiconductors. This has divided the world into two groups, chip makers and chip users In the case of chip making, there are a dozen of large chip makers. Of them, the five leading companies are Taiwan Semiconductor Manufacturing Company, Intel, Qualcomm, Broadcom, and Micron Technology. These five companies and a dozen of others spend a large sum of money on research and development to produce better and more efficient chips for the market. Hence, it is an industry which wholly driven by leading chip makers.

Entry of governments

It is only in recent years that the governments have entered the fray. Accordingly, the US government has offered a subsidy scheme of $ 52 billion to promote the semiconductor industry so that USA can become the market leader in the global semiconductor industry. Out of this, the lion’s share of $ 39 billion is earmarked for the startups. This money is to be used for semiconductor production, undertaking research on same, and developing the workers involved in the industry. It is reported that more than 460 companies have applied for receiving funds from the subsidy scheme. The numbers here are promising but like any subsidy scheme, it seems that the administrators of the scheme are worried only about the disbursement, known as the outlay goal, and not about the impact it will create in the US economy. That impact should show, if it is effective, a growing global share for US semiconductor industry, on one side, and invention and innovation of cutting-edge chip technologies, on the other.

India’s way of battling with chips

Sri Lanka’s neighbour to the north, India, which is also planning to increase its GDP from $ 3.7 trillion in 2023 to $ 10 trillion in 2035 has unveiled the $ 10 billion worth Semicon India Program in December 2021 (see: https://www.india-briefing.com/news/semicon-india-program-investment-incentives-manufacturing-design-semiconductors-industry-23860.html/). The long title of the program is the development of semiconductors and display manufacturing ecosystem in India. It has a sub scheme aiming at linking the designs to industry proper dedicated for 100 domestic companies, startups and micro, small, and medium enterprises or MSMEs which will form the backbone of the semiconductor industry in the country.

Since the outcome was not that fast, in July 2023, the Ministry of Electronics and Information Technology of India or MeitY modified the original scheme to make it more attractive (see: https://www.meity.gov.in/esdm/Semiconductors-and-Display-Fab-Ecosystem). Accordingly, a half of the project cost will be paid by the government for three specific categories of semiconductor industry: Setting up the fabrication of semiconductors, fabrication of displays or display fabs, and other components like compound semiconductors, silicon photonics, sensors, etc.

To make this a success, India is counting on some 300,000 odd design engineers available within the country as revealed in a panel discussion on the global semiconductor industry at the recently concluded World Economic Forum (access: https://www.youtube.com/watch?v=8SC1mFe0Y_k). In addition to these local companies, there are already a few top global players that include Micron Technology, Samsung, and Intel, that have set up production branches in India. The value of semiconductor industry in India in 2023 had been $ 7.76 billion. It is planned to increase this to $ 10.68 billion by 2027 (available at: https://www.statista.com/outlook/tmo/semiconductors/india#revenue).

|

Sri Lanka’s low-performing traditional exports

Sri Lanka’s semiconductor industry is yet to make a presence. But it will be an immense market opportunity in the future. This is because Sri Lanka’s present export basket has sustainability issues in the changing global production systems. Its traditional three – tree product exports –tea, rubber, and coconut – have already reached the saturation point as unprocessed export materials. Any growth in these exports should, therefore, be in value additions to be made. Its flagship export in the last three decades – apparel industry – faces several bottlenecks today.

One is the rising labour costs that have shifted the manufacturing base from Sri Lanka to low-wage countries like Bangladesh, Myanmar, and Cambodia. Another is the tendency today for apparel importing North American and European countries to set up factories on their own lands, called onshoring, and in countries with proximity, called near shoring. This has been made possible by the ever-improving automation of apparel manufacturing processes, a beneficiary of the development of the advanced semiconductors. Hence, high labour costs are not an obstacle anymore for apparel consuming countries.

Jumping on to Indian bandwagon

What this means is that Sri Lanka should necessarily add new products to its export basket. One such product is semiconductors. Since the country does not possess technology to manufacture it on its own, it should join with another country or a group of countries to produce the same as a partner. In this global production sharing network era, that is not a difficult task. In this connection, the best country for Sri Lanka to join with is India. In this context, Sri Lanka should not treat India as a threat but as a collaborative partner that offers it opportunities. Such an arrangement provides a ‘win-win’ situation to both countries. Sri Lanka can provide microchip wafers or undertake a part of the manufacturing process with its educated labour force. This is called working with production sharing networks.

Semiconductor solution

At this hour of severe economic crisis, Sri Lanka has no choice. With respect to domestic prices and exchange rate, it seems to be in an equilibrium. But that equilibrium which might change for the worse at any time is at a low level of output characterised by slow economic growth. The foreign exchange gap as projected by IMF while making the review of the extended fund facility in December 2023 is principally to be met by getting a generous foreign debt write-off amounting to $ 14 billion by both the bilateral lenders and commercial creditors. Since the total foreign debt to be restructured under the Government program is about $ 33 billion, the amount to be written off for providing relief to the gap is about 42% of the total. As it is, this is a highly challenging goal to attain. In these circumstances, the way out for Sri Lanka is to increase the earnings from the export of goods and services by a mega amount. The semiconductor industry provides an easy avenue for Sri Lanka in this regard. Hence, it is in the interest of the country to take early action to ride this wave by being a collaborative partner of India which is moving fast to make itself a semiconductor country soon.

(The writer, a former Deputy Governor of the Central Bank of Sri Lanka, can be reached at [email protected].)