Thursday Feb 12, 2026

Thursday Feb 12, 2026

Friday, 23 April 2021 00:00 - - {{hitsCtrl.values.hits}}

Many passenger vehicles, including three-wheelers and motorcycles are fuelled by octane 95 gasoline when octane 92 gasoline (petrol) is available at a lower price.

Do you pump Octane 95 Petrol to your car to get better performance? If your answer is ‘yes’, this article is for you.

Do you pump Octane 95 Petrol to your car to get better performance? If your answer is ‘yes’, this article is for you.

Otto engine (petrol engine) is an internal combustion spark ignition engine invented by a German engineer Nicolaus Otto in 1876 and used in most of the light weight vehicles including cars, three-wheelers and motor bicycles. Otto engines can burn most of the hydrocarbon fuels (including hydrogen and ethanol) that can mix with air by evaporation (low boiling point). But the combustion characteristics of different hydrocarbons are not the same when burned inside an engine. If an Otto engine is designed for a particular fuel, it would not perform similarly with a fuel that has a different chemical composition.

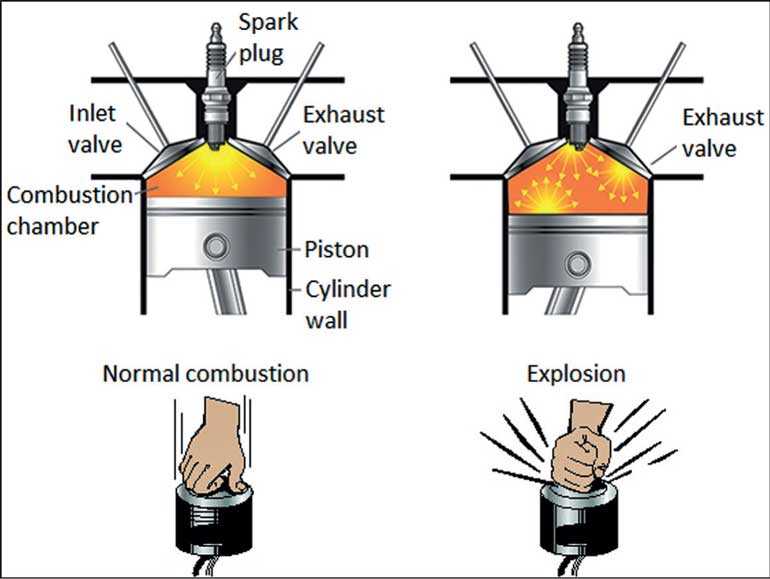

In a well-tuned Otto engine run on gasoline for which the engine is designed, the combustion of the gasoline (petrol)/air mixture will continue smoothly from the spark plug to the piston head by igniting successive layers of the mixture as shown in Figure 1 (a).

If low grade gasolines are used, the combustion of some of the air/fuel mixture in the cylinder does not result from propagation of the flame front initiated by the spark plug, but one or more pockets of air/fuel mixture explode (Detonate) outside the envelope of the normal combustion front as shown in Figure 1 (b). This detonation can cause severe damage to the piston and the head of the engine while deteriorating thermal performance of the engine (low efficiency).

Gasoline is a petroleum-derived product comprising a mixture of different hydrocarbons ranging from 4 to 12 carbon atoms in a carbon chain with the boiling point ranging of 30-225°C.

It is predominantly a mixture of paraffins, naphthenes, aromatics and olefins. Additives and blending agents are added to improve the performance and stability of gasoline. The engine designers learned that straight-chain paraffin have a much higher tendency to detonate than do branched-chain paraffin.

The tendency of a particular gasoline to detonate is expressed by its octane number (ON). Arbitrarily, tri-methyl-pentane, C8H18 (iso-octane) is assigned an ON of 100, while the straight-chain paraffin n-heptane, C7H16 is given an ON of zero. Hence, a fuel sample with the same anti-detonation quality as that of a mixture containing 90% iso-octane and 10% n-heptane is said to have an ON of 90. Gasoline is made up of a mixture of mostly branched-chain paraffin with suitable additives to give an ON in the range 90-100.

It was also learned through experiments that the ON of a gasoline blends (e.g. gasoline and ethanol) can be calculated by using weighted average ON of each compound. Most importantly, the octane number has nothing to do with the heating value (Calorific value) or the purity of the fuel.

Engine thermodynamics show that engines with a high compression ratio offer higher thermal performance than engines with a low compression ratio.

These engines having high compression ratio require high octane gasoline (for example octane 95) to avoid detonation. However, using gasoline having higher octane ratings for the engines designed for a low octane rating (for example, 92 octane) would not provide an additional benefit or loss, other than increased fuel cost.

Therefore, it is important to know the designed octane number of the engine before fuelling (refer owner’s manual of the vehicle). For example: the minimum ON requirement for two and three wheelers in south Asia is 87 (The World Bank). Most of the Toyota, Honda and Nissan models including hybrid engines recommend 92 octane gasoline.

Figure 1: Combustion characteristics of fuel/air mixture under compression: (a) Normal combustion, (b) explosion/detonation

(The writer received the B.Sc. degree in mechanical engineering from University of Moratuwa in 2001, and the M.Sc. and PhD degrees in decentralised power generation systems from Royal Institute of Technology Sweden and the Melbourne University Australia in 2004 and 2013 respectively. He has well over 13 years of national and international experience in design and installation of centralised/decentralised power plants, boilers (utility/package) and heat exchangers. Currently he is serving as a senior lecturer at University of Moratuwa, a visiting lecturer and fellow at Deakin University Australia.)