Saturday Feb 28, 2026

Saturday Feb 28, 2026

Friday, 7 July 2017 00:00 - - {{hitsCtrl.values.hits}}

When glancing at a glittering jewel or an intricate piece of jewellery, one rarely pauses to think of the tale that lies behind the glimmer and shimmer.

The production of gems and jewellery consists of three main segments – Lapidary Work, Jewellery Manufacturing and Laboratory Testing.

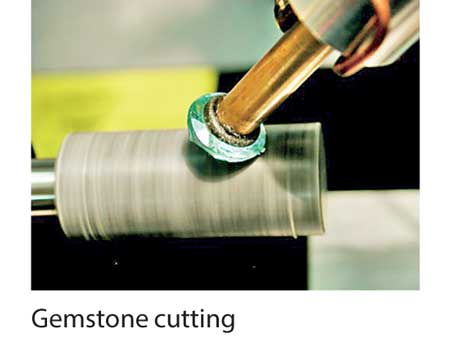

The lapidary industry is centred upon the artists/artisans (a.k.a. lapidaries) dedicated to cutting, polishing and engraving gemstones and other minerals, their task being to transform raw material into an object of value and beauty. It is said that the training period of a lapidary takes up to 10 years to complete.

The industry makes up a vital part of the gem and jewellery trade. Our island is home to most of the existing varieties of gemstones and its lapidary industry proudly boasts of over 2,000 years existence, during which Sri Lanka has shared its knowledge and expertise in the art with a number of foreign nations, including Tanzania and Madagascar.

Aside from the production and processing of minerals found in the country, the Sri Lankan Lapidary Industry is now capable of adding value to material brought to SL from foreign countries. A wide variety of machines and tools are employed in the task of manufacturing gems. In Sri Lanka, Lapidaries have adopted a semi-automated process, by use of international knowledge and technology, experts have fashioned an original local system of machines.

As of late, the lapidary industry also produces gems for the watch industry, which calls for work of the highest precision. (Stones are usually cut to a tolerance of 0.01 millimetres)

The field of jewellery manufacturing refers to the art of creating personal ornamental apparel using various metals such as gold, silver and platinum. After the casting, the work becomes manual – polishing, setting and plating, however there exists in Sri Lanka a handful of jewellers who use advanced technological systems in the entire process. Most Sri Lankan jewellers however prefer a blend of technology and manual. For example, a masterpiece is made by hand then sent to a machine in order to create a 3D form of the mould’s design, following which a second machine prints it out. This process is known as CAD/CAM services.

Today jewellery manufacturers are faced with a daunting challenge in the form of the diminishing number of smiths, while a fair amount of the existing jewellery makers, especially those living in rural villages, lack awareness about modern practices and technology.

The primary purpose of the gem and jewellery laboratories is to instil confidence in the buyer. The laboratories are operated by qualified gemmologists using state-of-the-art machinery who test the gems at two stages in the production process, before and after the mounting of them gem/gems. A buyer may also visit a laboratory himself/herself in order to test a gem or a piece of jewellery that they’ve purchased. The seller usually presents the certificate issued by the laboratory to the buyer at the time of purchase.

Organised by the Sri Lanka Gem and Jewellery Association, the FACETS International Gem and Jewellery Exhibition 2017 will feature a number of stalls featuring the tools used by lapidaries, the machines used in jewellery manufacturing as well as the equipment used in laboratories. Visitors may have the jewels they possess tested at the laboratory stalls and witness some of the basic processes followed by lapidaries and jewellers under one roof.