Tuesday Feb 17, 2026

Tuesday Feb 17, 2026

Wednesday, 9 October 2019 00:00 - - {{hitsCtrl.values.hits}}

The Total Marine Solutions (TMS) team of Diesel and Motor Engineering PLC (DIMO), one of the leading engineering companies in Sri Lanka, successfully concluded a complex repair of two MTU engines, on a super-luxury yacht based in a remote island in the Maldives, clearly defining DIMO’s stance and capabilities in extending their services to the region. A number of shipyards had been reluctant to take on this particular project as the owners came forth with very specific repair requirements.

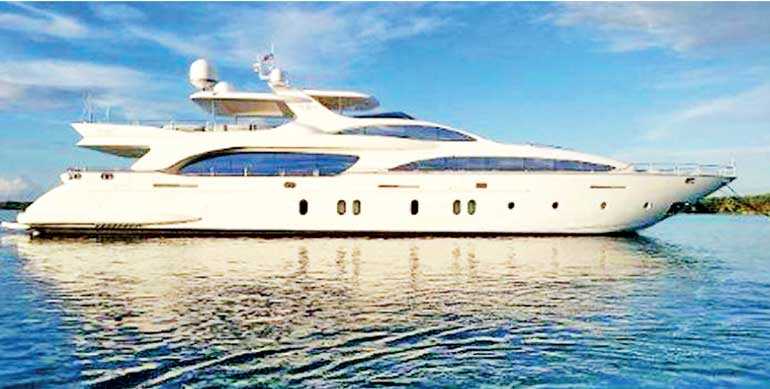

The yacht in question was an Azimut 98 Leonardo, and the design of the yacht in particular did not provide engine room access for the engines to be taken out during an overhaul. This would have meant cutting open the ship’s hull in order to take out the two engines. The owners did not want to attempt this, as it could have affected the appearance of the luxury yacht.

The TMS team undertook the project and subsequently devised an innovative solution by fabricating a special tool that could turn the engine inside the engine room in order to carry out the overhauling of both engines in situ.

Although repairs of this nature are generally conducted in dry docks or slipways, enduring very high costs, the TMS team carried out this activity while the vessel was afloat. One engine had completely seized due to oil starvation, damaging the crankshaft and the engine block. A crankshaft is a major component of a diesel engine, which transfers power to the propellers in order to achieve the required vessel speed. The engineers behind the project adopted a 360-degree innovative approach for this repair process and successfully salvaged the expensive engine block by carrying out a precision line boring of the crankcase. Their procedure, in turn, helped to save a large amount of money for the customer.

Commenting on the success of the recent repair undertaken by TMS, DIMO Chairman and Managing Director Ranjith Pandithage stated: “World-class brands require world-class people to manage and patronise the brand in any market. At DIMO, we are equipped with world-class people to provide the best type of care for the brands that we represent. This epitomises our capability, core competencies, and quality of workmanship in the field of engineering.”

Cheval Blanc Randheli in the Maldives assigned the overhaul of the yacht to DIMO TMS. Following the success of the project, Cheval Blanc Director of Engineering Randheli Nalin Maheepala stated: “Working with the DIMO TMS team was a pleasure as they were very professional and were able to execute the service by utilising limited facilities and resources at their harbour and that, too, within a limited time frame. They also ensured that the project was completed in a cost-effective manner. We are happy to have collaborated with such a reputed business organisation who no doubt did an excellent job, and we would happily recommend them for any marine-related service.”

Customarily, a standardised process needs to be adhered to when taking out the engines of a boat of this calibre in order to conduct a repair job. This exercise, if not done properly, would later affect the appearance of the boat. However, expert TMS engineers were able to conduct the repair process without disturbing the structure of the vessel and carrying out the engines repair inside the boat.

Following completion of the overhaul, sea trials were carried out to ascertain the performance of the diesel engines and the vessel successfully achieved the design speed of 24 knots. Commenting on the job, DIMO Director/General Manager Roshan Fernando indicated that the project took three and half months to complete.

This repair project, which seemed near impossible, was a challenging one, but was expertly handled by the DIMO TMS team. These types of undertakings demonstrate the range of expertise and the level of competency that the TMS experts possess. TMS incorporates a gamut of solutions that one can find under the marine industry. The team is well-positioned and capable of providing and implementing unparalleled solutions in the marine and general engineering space to the region.

DIMO branched out into marine engineering over 30 years ago and has established a reputation as the leader in its field. The company has partnered with world-renowned brands MTU and John Deere with world-class facilities for machining, pump calibration, and fuel injection repairs as per the international standards, contributing greatly to the high-quality ship repair service provided to clients.