Saturday Feb 21, 2026

Saturday Feb 21, 2026

Monday, 8 November 2021 02:23 - - {{hitsCtrl.values.hits}}

In the global sphere of industrial production, a highly specific position is established for the manufacture and assembly of automobiles, motorcar parts and components. With the advancement of technology, there exists a rapidly increasing competition among the countries and the world-renowned car manufacturing organisations in the field. The motivation of every manufacturer to offer the maximum satisfaction to the customer has now grown up to the level of autonomous cars.

In the global sphere of industrial production, a highly specific position is established for the manufacture and assembly of automobiles, motorcar parts and components. With the advancement of technology, there exists a rapidly increasing competition among the countries and the world-renowned car manufacturing organisations in the field. The motivation of every manufacturer to offer the maximum satisfaction to the customer has now grown up to the level of autonomous cars.

With a view to turning the State policy of enhancing local industries, Minister of Industries and Commerce Wimal Weerawansa has spearheaded the industrial manufacturing initiative and succeeded in obtaining Cabinet approval for the Standard Operating Procedure and getting it gazetted earlier this year, which aims at assembling and manufacturing motor vehicles. This is a great achievement, which had been lagging behind for over five years, and this has paved the way for local and foreign investors to enter the field with confidence and attracting much-needed FDIs to Sri Lanka.

Despite various countries have succeeded in introducing their products with different brands and the growth of this field in Sri Lanka is still at a primary level, two personalities come to mind who were dedicated to the progress of manufacturing cars, spare parts and assembling. One is late Upali Wijewardena, an illusions businessman, and the other is Deshamanya Dr. Lawrence Perera, professionally an automobile engineer, a veteran in the field of motor engineering and founder, Chairman and CEO of Micro Cars Ltd., with a car design patent – the first in Sri Lanka to prototype, develop and manufacture motor vehicles in commercial capacity in 2002.

This organisation deserves to be proud of being the sole local automobile assembly and manufacturing company with 100% local ownership, which by 2013 was of the capacity to export cars and light trucks to Nepal and Bangladesh and agro tractor machines to Malaysia.

A sizeable amount of annual foreign income has to be spent on the import of motor vehicles. While many countries manufacture motor vehicles to satisfy domestic and global demands, Sri Lanka seems to follow a policy of depending on vehicles, manufactured in foreign countries. Although there are few organisations that assemble motor vehicles locally, the lack of proper infrastructure facilities meeting to international standards makes the continuous existence of those organisations impossible. The dearth of companies, manufacturing vehicle parts, the barriers in finding technological competence and the needed capital are some of the problems, confronted with the industry.

As a result of the adoption of the Standard Operating Procedure for the assembly and manufacture of automobiles, the Government has recognised the importance of strategies implemented to enhance the local economy.

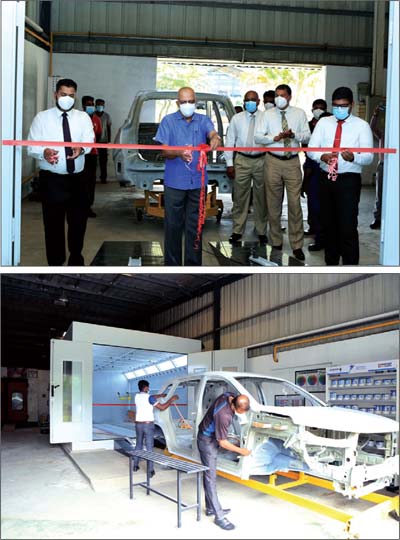

Micro Cars Ltd., a local company with three decades of experience in the field of automotive engineering having well understood the importance of state strategies to enhance domestic economy and the dreams of Sri Lankan customers, initiated its latest project of locally assembling the Micro MG Almaz seven-seater SUV, at the auspicious time on 26 October at its state-of-the-art assembling factory in Polghawela BOI Export Processing Zone.

Micro Cars is the first indigenous car manufacturer in Sri Lanka, claims to be the first local motor vehicle manufacturer to use water-based paint technology in the commercial assembling process. Overall, the contribution made by this method is worthwhile. There are a number of advantages that can be obtained from the thin paint coatings used in this method, as the toxic chemicals are very low, so the damages to the environment are minimal and the health of the factory production staff who contribute to the process is not threatened. It will also have a beneficial effect on the wallet of the end consumer.

The most impressive thing is the very clean finish given to the vehicle by the water base paint method. At the same time, this latest local painting facility for the car full body shell at the Micro factory will open up more training and employment opportunities for Sri Lankan youth and provide the necessary youth empowerment as well as the local value added percentage of locally assembled vehicles quantitatively as well as the quality of the assembly process is a matter of concern that has contributed to a rapid increase.

Micro MG Almaz is manufactured with a design pleasing the eyes of motor vehicle lovers of Sri Lanka. Equipped with powerful 1,500 CC turbo charged engine, fully auto gear system and panoramic sunroof facilities, the security measures of the vehicle include a circular camera system, cruise control, four air bags, ABS, EBD, break assist, hill hold control, electronic stability control, traction control system, EPB (Electronic Parking Break), 10.4-inch touchscreen multi-media system and seven-inch digital meter cluster which add much colour to the product.

Micro Cars is delighted to announce that this Micro MG Almaz SUV reaches customers at an unbelievable reasonable price with an unmatched guarantee. The efficient and friendly after sales service, uninterrupted supply of spare parts and RSA (roadside assistance) should also be specifically mentioned.