Sunday Feb 22, 2026

Sunday Feb 22, 2026

Saturday, 4 January 2020 00:05 - - {{hitsCtrl.values.hits}}

Behind the ‘clean’ wheel of the electric cars, there is a dark secret. The main element used to produce the batteries that power electric cars is cobalt – a toxic and hazardous element. Cobalt mining, which is a dangerous task, takes place in the Democratic Republic of Congo (DRC) which is home to 70% of the world’s cobalt supply. The mining of cobalt is unregulated and involves child labour, exploitation, human rights abuses and environmental risks to those who work on the mines

Compiled by Vandana Hettiaratchi

Compiled by Vandana Hettiaratchi

An article by Forbes in June 2019 titled ‘Electric Models to dominate car sales by 2040, wiping out 13 m barrels a day of oil demand’ made headlines as the demand for electric cars continues to rise exponentially, in most parts of the world. Globally, the sales of EVs grew from two million units in 2016 to 5 million in December 2018.

The need for Electric Vehicles (EVs) has come about as one of the solutions of tackling the environment crisis or the ‘climate emergency’, which the world is facing. Rising levels of greenhouse gases, mainly carbon dioxide (CO2), from the burning of fossil fuels, deforestation and dependence on technology has urged state governments to focus on investing in green technology, from which the idea of EVs, mainly cars, was born.

In the developed world, investment into green technology and ‘being sustainable’ is perceived as a “societal, moral and ethical” obligation and responsibility that both, the public and private sector, need to adhere to. Thus, the idea behind electric cars is that it is a cleaner and ‘greener’ alternative than using gasoline or petrol run cars. However, is the production and manufacturing of electric cars just as ‘green’? Just as ‘sustainable’?

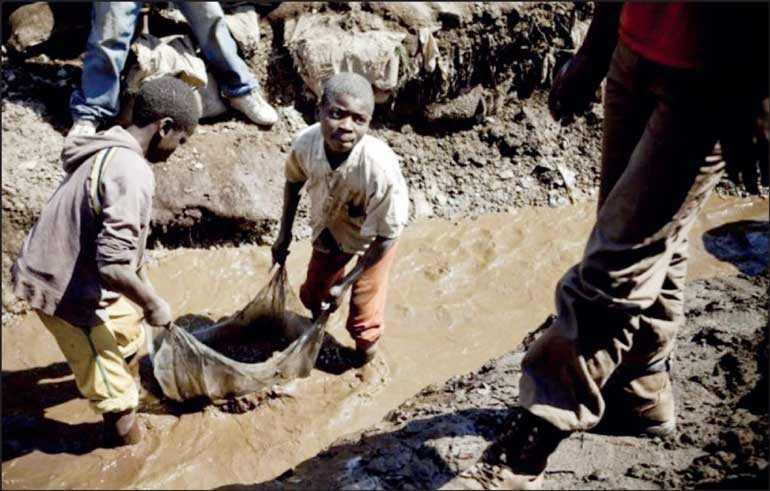

Behind the ‘clean’ wheel of the electric cars, there is a dark secret. The main element used to produce the batteries that power electric cars is cobalt – a toxic and hazardous element. Cobalt mining, which is a dangerous task, takes place in the Democratic Republic of Congo (DRC) which is home to 70% of the world’s cobalt supply.

The mining of cobalt is unregulated and involves child labour, exploitation, human rights abuses and environmental risks to those who work on the mines. Moreover, the manufacturing of electric cars emits more CO2 than the manufacturing of standard gasoline cars. Consequently, this undermines the ‘green potential’ of electric cars.

What is Green EVs and what is its benefit?

The United Nations defines it as “technology that has the potential to significantly improve environmental performance relative to other technology. Green technology holds the “promise that through innovative new technology, it is still possible to enjoy environmental improvement and maintain economic growth”.

The general consensus behind using green technology is that since it is made out of cleaner, renewable sources it does not discharge anything damaging to the atmosphere that could have a direct effect on the natural environment.

One of the sectors of research in green technology has been in the transportation sector, with heavy investment into Electric Vehicles (EVs), mainly cars. Despite still being relatively new with a representation of one out of every 250 motor vehicles on the road, the demand for electric cars has grown over the recent years.

In 2018 alone, car manufacturer Tesla delivered 100,000 electric cars per quarter. Several countries, including the UK have pledged to ban the sale of non-electric cars by 2030, in hope of addressing the climate emergency. EVs are thought to be more environmentally friendly, as it produces zero direct emissions (which include smog-forming pollutants and greenhouse gases) which improve the air quality.

Further, using battery operated or all electric cars produce lower emissions in energy generation than through burning of gasoline or diesel. Although from the surface it can be seen that electric cars are sustainable and good for the environment, the hidden reality behind its production and manufacturing is unknown.

Cobalt mining in DR Congo

The metal is an essential part of lithium-ion batteries used in electric vehicles. The demand for cobalt from the electric vehicle industry is expected to rise by 40% by the end of 2018 and continues to increase over the next decade. More than 50% of the world’s cobalt mine production comes from the Katanga Copper belt in DR Congo where a vast majority of miners – roughly 150,000 are employed by artisanal or small-scale mining. Despite being a profitable livelihood; the daily wage from cobalt mining is approximately $ 5 compared to a national daily income of less than $ 1.25, the artisanal cobalt mining manifests health and security risks to the miners. In most cases, the workers are exploited and unpaid.

The working hours of miners are long and extensive. An adult male miner works between eight to 12 hours per day, over the entire week. In addition, artisanal mining see miners working in dangerous, narrow underground tunnels up to 600ft below the surface and handling hazardous minerals without basic safety or protective equipment.

Child labour is also prevalent with 28% of the workforce, or 19,000-30,000 miners are under the age of 15. A majority of the children are often exploited orphans or street children. Children work approximately 12 hours in the mines for the opportunity to earn money and afford school fees.

Furthermore, the living conditions are dreadful. Cobalt particles in the soil make it dangerous for vegetables and consumption of these cause vomiting, diarrhoea, and fatal lung diseases including pneumonia. Diseases are rampant in the miners’ camps due to lack of sanitation and hygiene.

Women are subject to sexual harassment, abuse and rape and some are forced into prostitution. Girls, as young as ten, are subject to sexual attacks and many become pregnant. According to the United Nations, approximately 80 children die every year in the cobalt mines, although more deaths go unreported with bodies buried in the rubble of collapsed tunnels. Reading this makes us question whether the exploitation and inhumane treatment of children and adults is necessary for 15kg of cobalt to make one single electric car?

What can be done to make the mining more sustainable?

How is it possible to make the production and manufacturing of electric cars more ethical for the workers and environmentally friendly? There are several solutions. Firstly, the supply chain of cobalt mining should be more transparent and regulated.

Transport and environment have brought out six best practices that should be incorporated to ensure the sustainability in the cobalt supply chain: certification systems, monitoring and compliance from a panel of industry, government and NGO representatives, use of digital technology in the mines, adhering to human rights regulations, focus on enforcement and compliance schemes and public disclosure and transparency should be adhered to.

Secondly, governments in the global north and other countries, should start providing more awareness and improving policies to encourage citizens to use public transportation and increase taxes on the consumption and ownership of private vehicles. Thirdly, automotive companies should invest more into research and development, and find alternatives to lithium/cobalt-ion batteries for their electric cars- such as using more solar or wind powered vehicles. Fourthly, in DRC, itself, government corruption should be tackled, and laws should be improved to regulate the mining industry and the rights of those who work on the mines.

Does it work in reality?

However, while there are solutions, it is questionable whether it would big corporations of the global north, states and consumers would change their morals, ideas and thinking to improve the cobalt mining situation.

In a world driven by neo-liberal thinking, profit-maximisation and capitalism, dependent on fossil fuels and technology and highly material where ownership of a private vehicle is status-driven, change and improvement for the cobalt mining industry seems bleak. Improvement requires change from the entire system which, in my opinion, seems to be highly unlikely. Although it might be cleaner in terms of emissions, the ethics behind its production and manufacturing is anything but clean or green.

Capitalism, profit-maximisation and dependence on fossil fuels and non-renewable resources is never going to end. As sad it sounds, the situation of DR Congo and the cobalt mining industry is not going to improve for a long, long time.

(The writer holds a degree in International Relations from the University of London, UK. She is currently studying for her Master of Science programme in Development Studies at Lund University, Sweden, which was founded in 1666 and is ranked among the world’s top 100 universities. Email: [email protected])