Monday Feb 23, 2026

Monday Feb 23, 2026

Thursday, 29 July 2021 00:00 - - {{hitsCtrl.values.hits}}

Businesses constantly seek to improve their bottom line. In these troubled and competitive times, lowering costs with innovative means to optimize resource use in manufacturing is a sure way to get there. Any apparel sector operator can get behind that logic, regardless of business size. Resource wasting points in a business can be found by looking at the business value chain.

Businesses constantly seek to improve their bottom line. In these troubled and competitive times, lowering costs with innovative means to optimize resource use in manufacturing is a sure way to get there. Any apparel sector operator can get behind that logic, regardless of business size. Resource wasting points in a business can be found by looking at the business value chain.

Apparel Value Chains

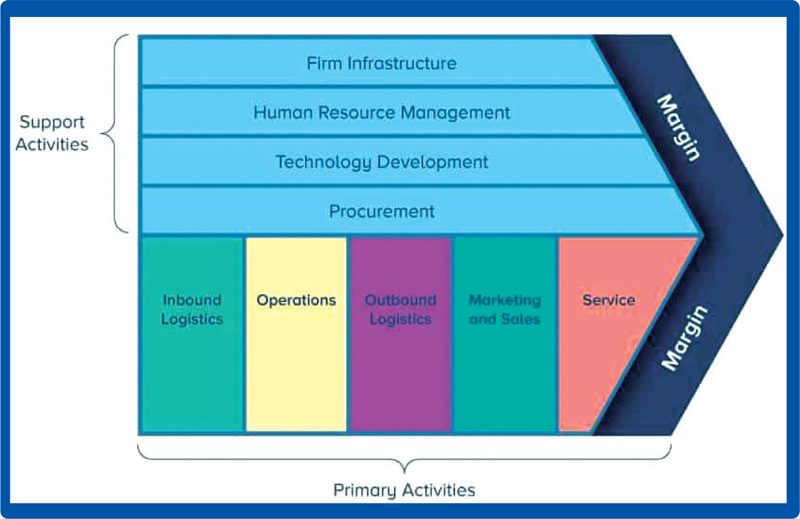

A business value chain connects the entire range of business activities that go into making and selling a product. Apparel value chain begins at the inputs to yarn that make up the fabric and ends with the recycling of the used item or its disposal as waste or incineration.

Value chain analysis helps increase production efficiencies that deliver value for the least possible cost.

There is a bundle of tools apparel manufacturers can use. These include Life Cycle Analysis, Cleaner Production, Zero Discharges, Science Based Targets and Renewable Energy Proportion. Alone or in combination, these tools help discover ways to optimize resources, reduce costs and boost profits while making businesses more sustainable.

Life Cycle Assessment (LCA)

Using LCA methods in their value discovery process helps apparel manufacturers assess the environmental impacts associated with their product life cycles.

Understanding the main stages of the product life cycle—material extraction, manufacturing, packaging, transportation, use and end of life—enables the discovery of potential savings at every step. There are potential gains and environmental benefits in addressing inputs, outputs, flow-throughs and value losses discovered. Cleaner Production and other tools help make the necessary changes.

Cleaner Production (CP)

Cleaner production is a preventive, integrated continuous strategy for modifying processes in order to enhance efficiency. This too results in better environmental performance and reductions in cost.

Good housekeeping, input substitution, better process controls, equipment modification, technology changes, onsite recovery and reuse, product modifications and more efficient energy use are CP practices that would help achieve a greener apparel value chain. When properly implemented, CP increases profitability and productivity. Improvements in product yields and efficient use of water, energy and raw materials lower production costs. Case studies show that CP delivers speedier returns on capital and operating investments with benefits far outweighing the costs.

Continuing these practices improve product quality, staff motivation and engagement while reducing consumer risks and environmental accidents.

Higg Index

Developed by the Sustainable Apparel Coalition, the Higg Index is a set of tools that help companies along the apparel value chain—brands, retailers, manufacturing and processing facilities—accurately measure and rate businesses or products on sustainability metrics.

Higg Index helps apparel makers accurately measure social and environmental impacts. They can find new ways to manage materials and natural resources. It also shows how to upskill workers and improve conditions to boost productivity by lowering staff turnover and absenteeism, burning problems for the apparel sector.

Supporting Green Businesses

Government of Sri Lanka and its regulatory agencies can promote greening within the apparel sector by applying regulations consistently and providing support measures.

Financing the Greening Process

Greening makes business sense and can boost productivity and profits of the apparel sector. It makes the industry more competitive and able to command a premium on products.

A key factor that prevents the adoption of more green measures is the cost and availability of funds. This is especially true in the case of small and medium enterprises.

Once convinced of their quantitative, qualitative and monetary benefits, apparel manufacturers can be provided with sustainable financing options to cover the costs of implementing green initiatives.

HSBC and IUCN have been working together to formulate a strategy to build a more resilient apparel industry through adoption of greener practices. “A Road Map Towards a Greener Apparel Sector” report is the result of an extensive research conducted by the project team in partnership with the Joint Apparels Association Forum, Board of Investment Sri Lanka, National Cleaner Production Centre and Sri Lanka Bankers’ Association.

To access the full report visit www.hsbc.lk/ApparelSectorResearch